జన . 23, 2025 04:08 Back to list

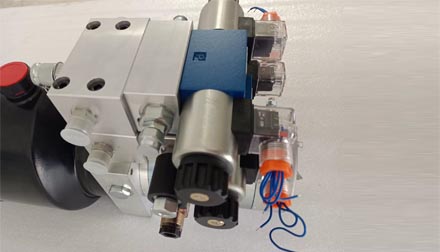

double acting power unit

High quality dump bed hydraulic cylinders are essential components in a variety of heavy-duty industrial and construction applications. They not only ensure the efficient operation of equipment but also contribute significantly to the safety and longevity of machines. As an industry professional with extensive experience in the heavy machinery sector, I understand the critical aspects to consider when selecting these components, which can significantly impact your operations.

Trustworthiness in hydraulic cylinder suppliers is evidenced through comprehensive warranties and excellent customer support. A company that stands behind its product will offer extensive guarantees, reassuring you of the product's longevity and performance. Furthermore, reputable suppliers provide technical support and maintenance services, which are invaluable for troubleshooting and prolonging the service life of hydraulic components. The installation and maintenance phases also underscore the quality of dump bed hydraulic cylinders. Expertly designed cylinders simplify the installation process, reducing setup time and costs. Additionally, comprehensive user manuals and support documents guide operators in routine inspections and maintenance procedures, preventing common issues that could potentially lead to operational failures. Moreover, an advanced hydraulic cylinder includes adjustable features such as variable stroke-lengths and pressure settings, which allow customization based on specific requirements of different projects. This adaptability enhances operational efficiency and maximizes the utility of your machinery across varied applications. Field experiences have shown that incorporating sensors and monitoring systems within the hydraulic cylinders can significantly improve performance metrics by providing real-time data on pressure and position. This technological integration helps in predictive maintenance, preventing unexpected breakdowns and facilitating timely interventions. Overall, the investment in high quality dump bed hydraulic cylinders is an investment in reliability, efficiency and long-term savings. Their impact on operational efficiency is substantial, from reducing downtime to enhancing the safety of lifting operations. When chosen wisely, these components are transformative in advancing your machinery capabilities, resulting in more successful project outcomes.

Trustworthiness in hydraulic cylinder suppliers is evidenced through comprehensive warranties and excellent customer support. A company that stands behind its product will offer extensive guarantees, reassuring you of the product's longevity and performance. Furthermore, reputable suppliers provide technical support and maintenance services, which are invaluable for troubleshooting and prolonging the service life of hydraulic components. The installation and maintenance phases also underscore the quality of dump bed hydraulic cylinders. Expertly designed cylinders simplify the installation process, reducing setup time and costs. Additionally, comprehensive user manuals and support documents guide operators in routine inspections and maintenance procedures, preventing common issues that could potentially lead to operational failures. Moreover, an advanced hydraulic cylinder includes adjustable features such as variable stroke-lengths and pressure settings, which allow customization based on specific requirements of different projects. This adaptability enhances operational efficiency and maximizes the utility of your machinery across varied applications. Field experiences have shown that incorporating sensors and monitoring systems within the hydraulic cylinders can significantly improve performance metrics by providing real-time data on pressure and position. This technological integration helps in predictive maintenance, preventing unexpected breakdowns and facilitating timely interventions. Overall, the investment in high quality dump bed hydraulic cylinders is an investment in reliability, efficiency and long-term savings. Their impact on operational efficiency is substantial, from reducing downtime to enhancing the safety of lifting operations. When chosen wisely, these components are transformative in advancing your machinery capabilities, resulting in more successful project outcomes.

Next:

Latest news

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025