Feb . 19, 2025 07:56 Back to list

china measuring a hydraulic cylinder

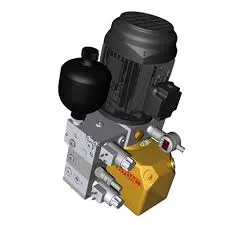

Accurate measurement of hydraulic cylinders is crucial for optimal performance, and doing it right ensures machinery operates smoothly and efficiently. Whether it is for industrial equipment, agricultural machines, or construction devices, understanding how to properly measure a hydraulic cylinder can greatly impact its lifespan and functionality. Here, we’ll dive deep into the essentials of measuring a hydraulic cylinder with a focus on ensuring your process is effective and accurate.

Another essential measurement is the cylinder port diameter - the internal diameter where hydraulic fluid enters and exits. The size of these ports can affect the hydraulic fluid flow rate, influencing the speed and power of the cylinder. Proper machination around this part operates to ensure efficient energy transfer while preventing leaks and operational delays. Equally important is considering the mounting style and dimensions, which include the distance between mounting holes or pins if relevant. Accurate configuration of these aspects ensures compatibility with machinery, reducing the potential for mechanical failure. Professional expertise in hydraulic systems greatly impacts the performance and safety of your equipment. Thus, verifying measurements using certified hydraulic measurement tools and adhering to industry standards establishes trustworthiness among consumers and businesses alike. It is advised to perform regular inspections and recalibration of your measuring tools to maintain high levels of accuracy and efficiency. This approach minimizes future downtimes and repairs, contributing to long-term savings and operational efficiency in the machinery. Finally, when taking these measurements, ensuring safety cannot be overlooked. Safety goggles and gloves must be used to counter any potential hazards from hydraulic oil or mechanical components, creating a secure environment for accurate and safe measurements. To conclude, measuring a hydraulic cylinder in China, or anywhere, requires precision, expertise, and reliable tools. Establishing a routine that includes these steps will enhance not only the performance but also the longevity of your hydraulic systems. Adopting these best practices builds a credible reputation for suppliers and users, solidifying their roles as industry leaders in hydraulic technology.

Another essential measurement is the cylinder port diameter - the internal diameter where hydraulic fluid enters and exits. The size of these ports can affect the hydraulic fluid flow rate, influencing the speed and power of the cylinder. Proper machination around this part operates to ensure efficient energy transfer while preventing leaks and operational delays. Equally important is considering the mounting style and dimensions, which include the distance between mounting holes or pins if relevant. Accurate configuration of these aspects ensures compatibility with machinery, reducing the potential for mechanical failure. Professional expertise in hydraulic systems greatly impacts the performance and safety of your equipment. Thus, verifying measurements using certified hydraulic measurement tools and adhering to industry standards establishes trustworthiness among consumers and businesses alike. It is advised to perform regular inspections and recalibration of your measuring tools to maintain high levels of accuracy and efficiency. This approach minimizes future downtimes and repairs, contributing to long-term savings and operational efficiency in the machinery. Finally, when taking these measurements, ensuring safety cannot be overlooked. Safety goggles and gloves must be used to counter any potential hazards from hydraulic oil or mechanical components, creating a secure environment for accurate and safe measurements. To conclude, measuring a hydraulic cylinder in China, or anywhere, requires precision, expertise, and reliable tools. Establishing a routine that includes these steps will enhance not only the performance but also the longevity of your hydraulic systems. Adopting these best practices builds a credible reputation for suppliers and users, solidifying their roles as industry leaders in hydraulic technology.

Next:

Latest news

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025