Nov . 24, 2024 16:57 Back to list

Top Manufacturers of Hydraulic Plunger Cylinders for Industrial Applications

Understanding Hydraulic Plunger Cylinder Manufacturers

Hydraulic plunger cylinders are crucial components in various industrial applications where controlled movement and force are required. These cylinders utilize hydraulic fluid to create motion through a plunger mechanism, enabling them to handle heavy loads efficiently. As the demand for hydraulic systems grows across different sectors, the role of hydraulic plunger cylinder manufacturers has become increasingly significant. This article delves into the importance of these manufacturers, their production processes, and the factors to consider when selecting a hydraulic plunger cylinder.

The Role of Hydraulic Plunger Cylinder Manufacturers

Manufacturers of hydraulic plunger cylinders design and produce a wide range of cylinders tailored to meet the unique needs of industries such as construction, manufacturing, automotive, and agriculture. The primary function of these cylinders is to convert hydraulic energy into mechanical energy, providing a means of lifting, pushing, or pulling heavy loads with precision. Manufacturers are responsible for developing reliable and durable products that can withstand high pressure and harsh operating conditions.

Production Processes

The production of hydraulic plunger cylinders involves several critical steps

1. Design and Engineering The process begins with comprehensive design and engineering. Manufacturers use computer-aided design (CAD) software to create detailed models that account for the specific requirements of different applications. Factors such as stroke length, diameter, and material strength are carefully considered.

2. Material Selection The choice of materials is paramount in ensuring the functionality and longevity of hydraulic cylinders. Manufacturers typically opt for high-strength steel or aluminum, which can withstand the pressures of hydraulic systems while resisting wear and corrosion.

3. Machining Once the design is finalized and materials selected, the machining process begins. This involves cutting, shaping, and finishing the cylinder components with precision. CNC (Computer Numerical Control) machines are often used to achieve the necessary tolerances and surface finishes.

4. Assembly After machining, the various components – including the cylinder body, piston, seals, and fittings – are assembled. This stage requires meticulous attention to detail to ensure that all parts fit together perfectly and can operate smoothly under pressure.

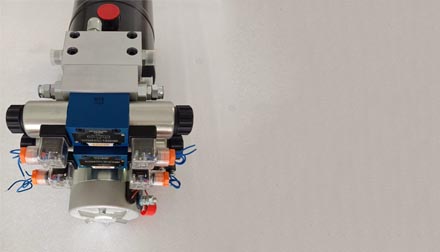

hydraulic plunger cylinder manufacturers

5. Testing and Quality Control Before a hydraulic plunger cylinder is released to the market, it undergoes rigorous testing. This includes pressure testing, leak testing, and performance evaluations to ensure that the cylinder meets safety and performance standards. Quality control is a critical aspect of the manufacturing process, as it directly influences the reliability and durability of the finished product.

Factors to Consider When Choosing a Manufacturer

When selecting a hydraulic plunger cylinder manufacturer, there are several key factors to keep in mind

1. Experience and Reputation Look for manufacturers with a proven track record and positive industry reputation. Experienced manufacturers are more likely to deliver high-quality products.

2. Customization Capabilities Different applications may require specific designs and features. A manufacturer that offers customization options can cater to unique requirements and enhance operational efficiency.

3. Quality Assurance Practices Investigate the quality control measures in place. Manufacturers that adhere to strict quality standards are more likely to produce reliable and durable products.

4. Customer Support Strong customer support can be invaluable, particularly when dealing with potential issues or inquiries regarding product specifications.

5. Certifications Consider manufacturers that hold relevant industry certifications, as this can be an indicator of their commitment to quality and safety.

Conclusion

Hydraulic plunger cylinder manufacturers play a vital role in the development and production of essential components for a variety of industries. By understanding the manufacturing processes and selecting the right manufacturer, businesses can ensure they are equipped with reliable hydraulic cylinders that enhance operational efficiency and safety. As industries continue to evolve, the expertise of these manufacturers will remain indispensable in driving innovation and performance.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025