Nov . 24, 2024 17:17 Back to list

Repackaging Solutions for Hydraulic Cylinder Products to Enhance Performance and Longevity

Repack Hydraulic Cylinder Products Ensuring Efficiency and Longevity in Hydraulic Systems

Hydraulic systems play a crucial role in various industries, providing the force needed to perform a multitude of tasks, from lifting heavy machinery to powering construction equipment. A key component of these systems is the hydraulic cylinder, which converts hydraulic energy into mechanical energy. However, over time, these cylinders can experience wear and tear, leading to leaks and reduced performance. This is where repacking hydraulic cylinder products come into play, offering a solution to extend the life and efficiency of these essential components.

What is Repacking?

Repacking a hydraulic cylinder involves replacing the worn seals and packing materials within the cylinder. This process is usually undertaken when a cylinder shows signs of leaking hydraulic fluid or is operating at a decreased efficiency. By repacking, you not only restore the function of the cylinder but also prevent further damage to the hydraulic system as a whole. This maintenance task can save businesses substantial costs associated with complete cylinder replacements and downtime.

The Importance of Quality Products

When repacking hydraulic cylinders, the choice of products used is critical. High-quality seals and packing materials can significantly enhance the performance and longevity of the hydraulic system. Materials such as polyurethane and rubber are commonly used due to their excellent durability and resistance to various chemicals and temperatures.

Opting for reputable manufacturers ensures that the repacking kits contain components specifically designed for your cylinder type. It is essential to use products that match the original design to avoid compatibility issues that could lead to further leaks or failures.

Benefits of Repacking Hydraulic Cylinders

1. Cost Efficiency Repacking is generally much less expensive than buying a new cylinder. By maintaining your existing equipment through repacking, you can utilize the same resources while extending the lifespan of your hydraulic system.

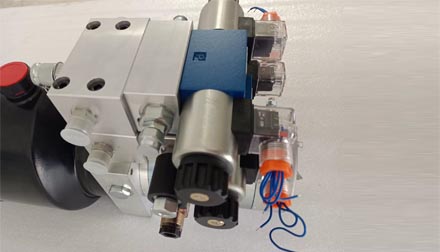

repack hydraulic cylinder products

2. Reduced Downtime The repacking process can often be completed relatively quickly, depending on the complexity of the hydraulics involved. This leads to minimal disruption to operations, as opposed to waiting for a new cylinder to be ordered and installed.

3. Environmental Impact By repacking and reusing existing hydraulic cylinders, you contribute to a reduction in waste. Manufacturing new cylinders involves raw materials and energy, whereas repacking utilizes existing components.

4. Enhanced Performance New seals and packing can drastically improve the efficiency of a hydraulic cylinder. With proper maintenance, hydraulic systems can run more smoothly and effectively, which in turn can improve overall system performance.

5. Safety Leaking hydraulic fluids pose safety risks in the workplace, including slips and falls or equipment failure. Regular inspection and repacking of hydraulic cylinders can mitigate these dangers, ensuring a safer working environment.

When to Consider Repacking

Regular maintenance checks are essential for any hydraulic system. Key indicators that a hydraulic cylinder may need repacking include visible leaks, decreased performance, unusual noises during operation, or extended actuator times. By addressing these signs early on, you can prevent more severe complications and costly repairs.

Conclusion

Repacking hydraulic cylinders is an integral aspect of hydraulic maintenance, providing a cost-effective solution that enhances system performance and longevity. Using quality repacking products ensures that your equipment operates efficiently and safely. By staying proactive with maintenance and repacking when necessary, industries can maximize their investments in hydraulic systems, ensuring reliable and effective operations for years to come. Proper repacking not only ensures the hydraulic cylinder's performance, but also contributes positively to the overall productivity and sustainability of the business. Whether you are managing heavy machinery in construction or operating complex manufacturing equipment, prioritizing the maintenance of hydraulic cylinders through repacking is a wise strategy for any operator looking to achieve efficiency and save costs.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Heavy-Duty Lifting Solutions&Precision Engineering

NewsJul.21,2025