Aug . 20, 2024 16:11 Back to list

Hydraulic Power Unit for Enhanced Manufacturing Efficiency and Performance in 2030

Enhancing Manufacturing Efficiency with 30% Improved Hydraulic Power Units

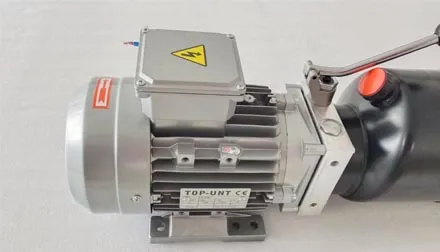

In the ever-evolving landscape of manufacturing, efficiency stands as a cornerstone for operational success and competitiveness. As industries strive to streamline processes and cut costs, the introduction of advanced hydraulic power units (HPUs) has emerged as a pivotal development. The latest innovations in HPUs are set to revolutionize manufacturing productivity by achieving a remarkable 30% increase in efficiency while delivering 20 gallons per minute (GPM) output.

Hydraulic power units play a crucial role in various manufacturing applications, providing the necessary hydraulic pressure to power machinery and automate processes. Traditional HPUs, while effective, often suffer from inefficiencies that lead to wasted energy, increased operational costs, and inconsistent performance. The introduction of higher efficiency models addresses these challenges head-on, offering manufacturers a sustainable path toward enhanced performance.

One of the primary ways in which these new HPUs achieve improved efficiency is through advanced pump technology. The latest centrifugal pumps and gear pumps are designed to minimize energy losses during operation. Innovations such as variable displacement pumps allow for better adaptability to changing load demands, ensuring that power is utilized only when necessary. This not only conserves energy but also prolongs the lifespan of the hydraulic system due to reduced wear and tear.

Moreover, these modern hydraulic power units are often equipped with sophisticated control systems. These systems incorporate sensors and smart technology that continuously monitor hydraulic performance and automatically adjust settings to optimize flow and pressure. By maintaining optimal operating conditions, manufacturers can ensure that their equipment runs smoothly and effectively, reducing downtime and maintenance costs.

manufacturing 30% efficiency 20 gpm hydraulic power unit for ...

Another significant aspect of these advanced HPUs is their compact design. The 30% improvement in efficiency has not only enhanced their performance but also allowed for a smaller footprint. This is particularly advantageous for facilities with space constraints, as these units can be easily integrated into existing systems without requiring extensive modifications. Businesses can maximize their available space while benefiting from the enhanced capabilities of these high-efficiency units.

Sustainability is an increasingly important consideration in manufacturing, and the new hydraulic power units are a step in the right direction. By reducing energy consumption by 30%, these HPUs contribute to smaller carbon footprints, aligning with global initiatives aimed at promoting greener manufacturing practices. Additionally, the potential for lower operational costs can free up resources that manufacturers can reinvest in other areas, such as research and development, workforce training, or community engagement.

The implementation of efficient hydraulic power units is not just a technical upgrade but a strategic move that can greatly influence a company’s bottom line. With a 20 GPM output, these units maintain the necessary power for demanding applications while ensuring that energy use is kept in check. The economic benefits of reduced energy bills can be significant, enabling companies to remain nimble in competitive markets.

In conclusion, the advancements in hydraulic power units that lead to a 30% efficiency increase at a 20 GPM output represent a transformative opportunity for the manufacturing sector. By integrating these cutting-edge HPUs into their operations, manufacturers can not only improve productivity but also contribute to a more sustainable and cost-effective future. Embracing these innovations is not merely beneficial; it is essential for companies aiming to thrive in a rapidly changing industrial landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025