Aug . 20, 2024 17:00 Back to list

China's Innovative Double-Ended Hydraulic Cylinder Technology for Enhanced Performance and Efficiency

The Significance of Double-Ended Hydraulic Cylinders in China's Industrial Landscape

In recent years, the evolution of hydraulic technologies has propelled significant advancements across various sectors in China, with double-ended hydraulic cylinders playing a pivotal role. These robust hydraulic devices are known for their versatility, efficiency, and reliability, making them essential components in numerous industrial applications, including construction, manufacturing, and automation.

A double-ended hydraulic cylinder is distinguished by its capability to exert force from both ends, allowing for a more balanced and efficient operation. This design feature enables manufacturers to achieve higher levels of precision and power in their machinery, which is particularly valuable in heavy-load applications. In the context of China's booming construction industry, these cylinders are fundamental in powering cranes, excavators, and other heavy equipment essential for large infrastructure projects.

The Significance of Double-Ended Hydraulic Cylinders in China's Industrial Landscape

Moreover, China's manufacturing sector benefits greatly from the versatility of double-ended hydraulic cylinders. They are employed in various machinery, including metal forming presses, stamping machines, and injection molding equipment. By facilitating precise movements and high force outputs, these cylinders help improve production efficiency and product quality. As Chinese manufacturers strive to meet global standards and increased demand for high-quality products, the importance of advanced hydraulic technologies, including double-ended cylinders, continues to grow.

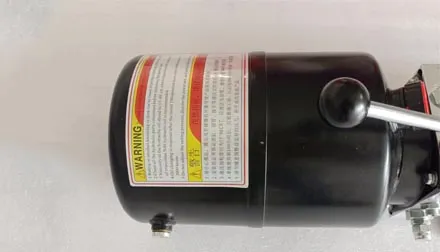

china double ended hydraulic cylinder

The adoption of double-ended hydraulic cylinders is also driven by the need for sustainability in industrial operations. As environmental concerns gain prominence, many industries are exploring more efficient machinery options that minimize energy consumption. Hydraulic systems generally provide superior energy efficiency when compared to mechanical systems, and double-ended cylinders optimize this efficiency further. By reducing energy waste and improving operational effectiveness, these cylinders align with China's goals for sustainable industrial growth.

In recent years, advancements in materials science and engineering have also contributed to the evolution of double-ended hydraulic cylinders. Manufacturers in China are increasingly using high-strength alloys and composite materials that offer improved durability and resistance to wear and tear. This enhancement not only extends the lifespan of hydraulic cylinders but also reduces maintenance costs and downtime, essential factors for industries operating under tight schedules and budgets.

Furthermore, the rise of automation and smart technologies in manufacturing has integrated hydraulic systems with sophisticated control systems. Through advanced sensors and data analytics, double-ended hydraulic cylinders can be monitored in real time, allowing for predictive maintenance and increased operational reliability. This integration of technology is vital for enhancing productivity and maintaining competitive advantages in the fast-paced global market.

In summary, double-ended hydraulic cylinders serve as a cornerstone in China's industrial landscape, providing the necessary force, precision, and efficiency crucial for various applications. Their ability to work in confined spaces, support sustainable operations, and integrate with advanced control systems makes them an invaluable asset for industries striving for innovation and excellence. As China continues to evolve as a manufacturing powerhouse, the role of double-ended hydraulic cylinders will undoubtedly expand, shaping the future of industrial machinery and technological advancement.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025