شوبات . 12, 2025 09:16 Back to list

china leaking hydraulic cylinder

China's market for hydraulic cylinders has been expanding rapidly, driven by the increasing demand in various sectors such as construction, agriculture, and manufacturing. Despite this robust growth, one pressing issue faced by many users is the problem of leaking hydraulic cylinders. This article delves into practical solutions for tackling this problem, combining real-world experience with expert advice and industry insights to provide a comprehensive guide.

Expert knowledge suggests employing advanced technologies in predictive maintenance will significantly reduce the likelihood of leaks. Sensors that monitor pressure, temperature, and humidity in real-time can offer early warnings of potential failures, allowing operators to take corrective actions proactively. Consider investing in smart hydraulic systems that integrate these technologies for a more resilient and efficient setup. A deeper understanding of China’s manufacturing landscape reveals the importance of selecting the right supplier. Engage with companies that have a proven track record of delivering reliable products. It's prudent to demand transparency regarding the materials used and the QC processes employed during production. Chinese suppliers that offer bespoke solutions tailored to specific industry requirements can provide added advantages. Authoritative voices in the industry recommend leveraging global networks for parts and service provision. While China offers cost advantages, combining domestic benefits with international expertise can ensure superior quality and longevity of hydraulic systems. By creating strategic partnerships with foreign companies experienced in hydraulic technology, users can access premium components and technical consultation. Trustworthiness in the industry is built on transparency and customer-centric service. Opt for suppliers who offer comprehensive warranties and responsive after-sales support. Reading customer reviews and soliciting feedback from industry peers can further guide decision-making processes. In summary, resolving the challenge of leaking hydraulic cylinders in China requires a multi-faceted approach that incorporates superior materials, expert installation, proactive maintenance, advanced technology, strategic supplier selection, and reliable customer support. This holistic strategy not only extends the lifecycle of hydraulic systems but also enhances overall operational efficiency. With the right knowledge, tools, and partnerships, users can mitigate leaks and harness the full potential of hydraulic technology.

Expert knowledge suggests employing advanced technologies in predictive maintenance will significantly reduce the likelihood of leaks. Sensors that monitor pressure, temperature, and humidity in real-time can offer early warnings of potential failures, allowing operators to take corrective actions proactively. Consider investing in smart hydraulic systems that integrate these technologies for a more resilient and efficient setup. A deeper understanding of China’s manufacturing landscape reveals the importance of selecting the right supplier. Engage with companies that have a proven track record of delivering reliable products. It's prudent to demand transparency regarding the materials used and the QC processes employed during production. Chinese suppliers that offer bespoke solutions tailored to specific industry requirements can provide added advantages. Authoritative voices in the industry recommend leveraging global networks for parts and service provision. While China offers cost advantages, combining domestic benefits with international expertise can ensure superior quality and longevity of hydraulic systems. By creating strategic partnerships with foreign companies experienced in hydraulic technology, users can access premium components and technical consultation. Trustworthiness in the industry is built on transparency and customer-centric service. Opt for suppliers who offer comprehensive warranties and responsive after-sales support. Reading customer reviews and soliciting feedback from industry peers can further guide decision-making processes. In summary, resolving the challenge of leaking hydraulic cylinders in China requires a multi-faceted approach that incorporates superior materials, expert installation, proactive maintenance, advanced technology, strategic supplier selection, and reliable customer support. This holistic strategy not only extends the lifecycle of hydraulic systems but also enhances overall operational efficiency. With the right knowledge, tools, and partnerships, users can mitigate leaks and harness the full potential of hydraulic technology.

Latest news

-

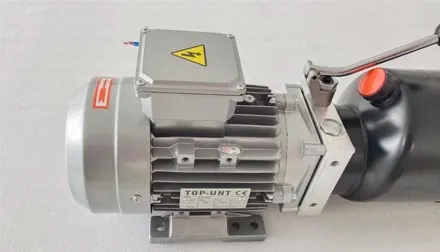

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025