ژانویه . 20, 2025 06:07 Back to list

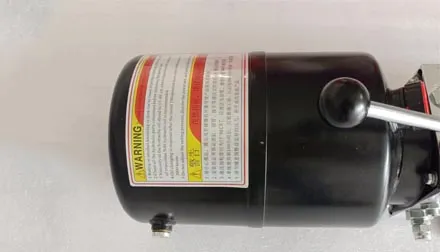

high quality hydraulic downfeed cylinder

High-quality hydraulic downfeed cylinders have emerged as indispensable components in various industrial and commercial applications. Their reliability, efficiency, and performance are crucial to the smooth operation of numerous machines and systems. For those seeking to improve their understanding of these essential tools, this article provides an authoritative and trustworthy guide based on real-world experience and professional expertise.

Professionals using these cylinders also appreciate the significance of customization and adaptability. Leading manufacturers offer tailored solutions that align with specific project requirements, ensuring that every hydraulic cylinder is a perfect fit for its intended application. Such bespoke solutions increase the applicability and versatility of these cylinders, allowing users to confidently implement them in diverse scenarios. From a maintenance standpoint, high-quality hydraulic downfeed cylinders are designed with accessibility in mind. They often feature components that can be easily serviced or replaced, reducing downtime during maintenance. This focus on user-friendly design reflects a deeper understanding of the practical challenges faced by industry professionals, making these cylinders not just a tool, but an ally in the field. Hydraulic downfeed cylinders also score high on ecological and economic fronts. High precision and efficient operation mean that there is less energy wastage, contributing to lower operational costs and a reduced carbon footprint. This aligns with modern-day sustainability goals and economic efficiency, making them an attractive option for businesses aiming to enhance their green credentials while maintaining fiscal responsibility. For those stepping into roles requiring the use of hydraulic cylinders, it's essential to engage with suppliers who prioritize innovation and quality. Industry experts agree that the hallmark of a dependable hydraulic cylinder is its certification and compliance with international standards. Such credentials are a testament to the manufacturer's commitment to quality and to delivering products that can reliably perform under stringent conditions. In summary, high-quality hydraulic downfeed cylinders are vital components that offer an ideal blend of performance, durability, and flexibility. Their role in enhancing the efficiency of mechanical systems is unparalleled, making them crucial for industries keen on optimizing performance while ensuring economic and environmental responsibility. As technology advances further, we can look forward to even more sophisticated iterations, affirming their place within the pantheon of indispensable industrial tools.

Professionals using these cylinders also appreciate the significance of customization and adaptability. Leading manufacturers offer tailored solutions that align with specific project requirements, ensuring that every hydraulic cylinder is a perfect fit for its intended application. Such bespoke solutions increase the applicability and versatility of these cylinders, allowing users to confidently implement them in diverse scenarios. From a maintenance standpoint, high-quality hydraulic downfeed cylinders are designed with accessibility in mind. They often feature components that can be easily serviced or replaced, reducing downtime during maintenance. This focus on user-friendly design reflects a deeper understanding of the practical challenges faced by industry professionals, making these cylinders not just a tool, but an ally in the field. Hydraulic downfeed cylinders also score high on ecological and economic fronts. High precision and efficient operation mean that there is less energy wastage, contributing to lower operational costs and a reduced carbon footprint. This aligns with modern-day sustainability goals and economic efficiency, making them an attractive option for businesses aiming to enhance their green credentials while maintaining fiscal responsibility. For those stepping into roles requiring the use of hydraulic cylinders, it's essential to engage with suppliers who prioritize innovation and quality. Industry experts agree that the hallmark of a dependable hydraulic cylinder is its certification and compliance with international standards. Such credentials are a testament to the manufacturer's commitment to quality and to delivering products that can reliably perform under stringent conditions. In summary, high-quality hydraulic downfeed cylinders are vital components that offer an ideal blend of performance, durability, and flexibility. Their role in enhancing the efficiency of mechanical systems is unparalleled, making them crucial for industries keen on optimizing performance while ensuring economic and environmental responsibility. As technology advances further, we can look forward to even more sophisticated iterations, affirming their place within the pantheon of indispensable industrial tools.

Latest news

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025