فبراير . 01, 2025 03:55 Back to list

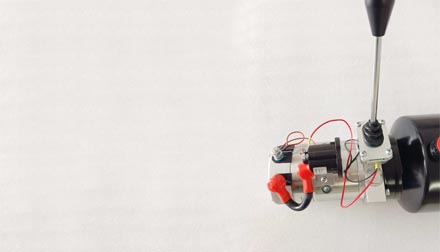

high quality wear band hydraulic cylinder

The hydraulic cylinder, a pivotal component in modern machinery and industrial applications, has witnessed continuous evolution, resulting in various improvements that meet the needs of diverse industries. Among these advancements, the high-quality wear band hydraulic cylinder stands out due to its unique features and high-performance capabilities. With years of experience in engineering and manufacturing excellence, we delve into the intricacies of this remarkable product, providing insights into its benefits, applications, and why it commands trust in the marketplace.

The expertise embedded in the engineering process of these hydraulic cylinders is evident in their design optimization. Engineers have strategically implemented state-of-the-art technologies and methodologies to enhance load distribution and minimize the risk of cylinder distortion under pressure. This innovation ensures that these cylinders deliver superior performance while maintaining structural integrity over extended periods. Furthermore, rigorous testing and quality control processes are in place to ensure each cylinder meets industry standards for safety and reliability. From a customer standpoint, the authoritativeness of these high-quality wear band hydraulic cylinders is enhanced by third-party certifications and compliance with international standards. This adherence to globally recognized benchmarks assures clients of their robustness and reliability, instilling confidence that these components can withstand the demands of even the most challenging operational environments. The trust established in these hydraulic cylinders is fortified by the testimonials of seasoned professionals who have employed them in their machinery. Reports from field operators emphasize the reduction in maintenance downtime and the associated cost savings, attributing these benefits to the reliability provided by the wear band components. Such firsthand experiences are invaluable, proving that these cylinders not only meet but often exceed the expectations of end-users. In conclusion, high-quality wear band hydraulic cylinders represent a fusion of sophisticated engineering, robust materials, and a commitment to excellence in hydraulic system design. Their tailored features and proven performance across various industrial applications highlight their indispensability in modern mechanical operations. As manufacturers continue to push the boundaries of hydraulic technology, these cylinders will undoubtedly remain a cornerstone of innovation, demonstrating their enduring relevance in an ever-evolving industrial landscape.

The expertise embedded in the engineering process of these hydraulic cylinders is evident in their design optimization. Engineers have strategically implemented state-of-the-art technologies and methodologies to enhance load distribution and minimize the risk of cylinder distortion under pressure. This innovation ensures that these cylinders deliver superior performance while maintaining structural integrity over extended periods. Furthermore, rigorous testing and quality control processes are in place to ensure each cylinder meets industry standards for safety and reliability. From a customer standpoint, the authoritativeness of these high-quality wear band hydraulic cylinders is enhanced by third-party certifications and compliance with international standards. This adherence to globally recognized benchmarks assures clients of their robustness and reliability, instilling confidence that these components can withstand the demands of even the most challenging operational environments. The trust established in these hydraulic cylinders is fortified by the testimonials of seasoned professionals who have employed them in their machinery. Reports from field operators emphasize the reduction in maintenance downtime and the associated cost savings, attributing these benefits to the reliability provided by the wear band components. Such firsthand experiences are invaluable, proving that these cylinders not only meet but often exceed the expectations of end-users. In conclusion, high-quality wear band hydraulic cylinders represent a fusion of sophisticated engineering, robust materials, and a commitment to excellence in hydraulic system design. Their tailored features and proven performance across various industrial applications highlight their indispensability in modern mechanical operations. As manufacturers continue to push the boundaries of hydraulic technology, these cylinders will undoubtedly remain a cornerstone of innovation, demonstrating their enduring relevance in an ever-evolving industrial landscape.

Latest news

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025