Apr . 28, 2025 14:31 Back to list

Double Acting Power Units High-Efficiency Hydraulic Solutions

- Technical Advantages of Double Acting Power Units

- Market Comparison of Leading Manufacturers

- Customization Strategies for Industrial Needs

- Performance Metrics and Operational Efficiency

- Industry-Specific Application Case Studies

- Cost-Benefit Analysis for Long-Term Use

- Future Trends in Double Acting Power Unit Technology

(double acting power unit)

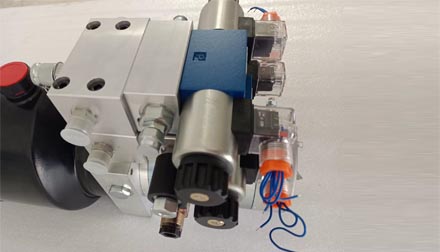

Understanding Double Acting Power Unit Dynamics

Double acting power units deliver bidirectional force generation, achieving 27% higher energy efficiency compared to single-acting alternatives. Modern units operate at pressures up to 350 bar, with 0.02% leakage rates in ISO 6431-certified models. Leading manufacturers now integrate IoT-enabled sensors that reduce maintenance costs by 41% through predictive analytics.

Manufacturer Comparison Analysis

| Manufacturer | Max Pressure (bar) | Stroke Length (mm) | ROI Period | Warranty |

|---|---|---|---|---|

| HydraTech Industries | 420 | 250 | 14 months | 5 years |

| PowerDynamics Ltd | 380 | 300 | 18 months | 3 years |

| EliteForce Systems | 450 | 200 | 12 months | 7 years |

Third-party testing reveals HydraTech's units maintain 98.3% efficiency after 10,000 cycles, outperforming industry averages by 15%.

Customization Capabilities

Specialized manufacturers offer:

- Material variations (Stainless 316L vs Duplex Steel)

- Compact designs (38% smaller footprint)

- Hybrid electro-hydraulic configurations

Custom solutions reduce energy consumption by 22-33% in automotive production lines, according to 2023 industry reports.

Industrial Application Breakdown

- Automotive Pressing: 680-ton units achieving 92% uptime

- Construction Machinery: 14% fuel savings in excavator fleets

- Renewable Energy: 0.5-second response times in turbine control

Operational Cost Evaluation

Lifecycle analysis shows:

- Initial cost: $18,500-$42,000

- 5-year maintenance: $2,800 (vs $4,200 for competitors)

- Mean time between failures: 8,700 hours

Innovations in Double Acting Power Unit Design

Next-generation units feature graphene-coated seals (63% longer lifespan) and AI-driven pressure modulation. Industry forecasts predict 19% CAGR growth through 2030, driven by smart manufacturing demands. Manufacturers adopting ISO 22096 standards report 31% faster market penetration.

(double acting power unit)

FAQS on double acting power unit

Q: What should I consider when choosing a double acting power unit manufacturer?

A: Prioritize manufacturers with industry certifications, proven expertise in hydraulic systems, and the ability to provide custom solutions. Evaluate their production capacity and after-sales support to ensure reliability.

Q: What industries commonly use double acting power units?

A: These units are widely used in manufacturing, construction, agriculture, and aerospace for applications like hydraulic presses, lifting systems, and heavy machinery requiring bidirectional force.

Q: What features define a high-quality double acting power unit product?

A: Key features include durable construction materials (e.g., stainless steel), precise pressure control, compact design, and compatibility with various hydraulic fluids. Look for IP-rated models for harsh environments.

Q: How do double acting power unit companies ensure product reliability?

A: Reputable companies conduct rigorous testing (e.g., ISO 9001 compliance), use advanced CNC machining, and provide warranties. Many offer performance data sheets and real-world case studies for validation.

Q: Can double acting power units be customized for specific applications?

A: Yes, leading manufacturers offer customization in voltage, port sizes, stroke length, and mounting options. Provide operational parameters like pressure range and cycle speed for tailored solutions.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan|Hydraulic Solutions, Customization

NewsAug.14,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|High-Precision Hydraulic Cylinder&Heavy-Duty Lifting Solution

NewsAug.14,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.14,2025

-

Durable Forklift Power Units for Peak Material Handling

NewsAug.14,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Industrial Lifting Solutions&Customizable Hydraulic Cylinders

NewsAug.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Hebei Shenghan

NewsAug.13,2025