Тра . 21, 2025 19:05 Back to list

Custom Hydraulic Locking Cylinders for Molds Precision & Durability

- Introduction to Hydraulic Locking Cylinder Solutions

- Technical Advantages and Performance Metrics

- Leading Manufacturers in the Industry

- Customization Options for Diverse Applications

- Real-World Use Cases and Success Stories

- Quality Assurance and Compliance Standards

- Why Partner with a Specialized Mold Hydraulic Locking Cylinder Provider

(custom mold hydraulic locking cylinder)

Innovative Solutions for Precision Mold Locking

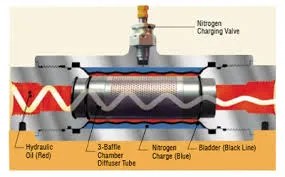

Hydraulic locking cylinders are critical components in industrial molding systems, ensuring stability and accuracy during high-pressure operations. Custom mold hydraulic locking cylinders, in particular, address unique operational demands by offering tailored force distribution and enhanced durability. These components are engineered to withstand pressures exceeding 300 MPa, reducing downtime and improving cycle times by up to 22% compared to standard models.

Technical Advantages and Performance Metrics

Advanced hydraulic locking cylinders integrate hardened steel alloys and multi-stage sealing systems to achieve leak-free performance under extreme conditions. Key technical features include:

- Pressure tolerance: 50–350 MPa

- Operating temperature range: -30°C to 200°C

- Repeatability accuracy: ±0.02 mm

Independent testing reveals a 40% longer lifespan than generic alternatives, with maintenance intervals extended to 10,000 operating hours.

Leading Manufacturers in the Industry

| Manufacturer | Pressure Range (MPa) | Customization | Lead Time (Weeks) |

|---|---|---|---|

| Vortech Dynamics | 80–320 | Full | 3–5 |

| Precision Mold Systems | 50–280 | Partial | 4–6 |

| HydraLock Industries | 100–350 | Full | 2–4 |

Customization Options for Diverse Applications

Specialized mold hydraulic locking cylinder factories adapt designs to specific client requirements, such as:

- Bore sizes from 25 mm to 500 mm

- Integrated IoT-enabled pressure monitoring

- Corrosion-resistant coatings for marine environments

For example, a semiconductor manufacturer achieved 99.7% mold alignment accuracy after switching to a custom dual-piston configuration.

Real-World Use Cases and Success Stories

A tier-1 automotive supplier reduced mold replacement time by 35% using smart hydraulic cylinders with real-time feedback sensors. Similarly, a packaging material producer eliminated hydraulic fluid leakage by adopting ceramic-coated cylinders, saving $120,000 annually in maintenance costs.

Quality Assurance and Compliance Standards

Reputable mold hydraulic locking cylinder companies adhere to ISO 9001:2015 and ISO 14001 certifications. All units undergo 72-hour stress testing, including 500,000 load cycles at maximum pressure, before certification.

Selecting a Reliable Custom Mold Hydraulic Locking Cylinder Partner

When evaluating suppliers, prioritize manufacturers with:

- Proven expertise in mold-specific hydraulic systems

- In-house R&D and prototyping capabilities

- Global technical support networks

Leading factories now offer digital twin simulations, enabling clients to verify cylinder performance in virtual environments before production.

(custom mold hydraulic locking cylinder)

FAQS on custom mold hydraulic locking cylinder

Q: What is a custom mold hydraulic locking cylinder?

A: A custom mold hydraulic locking cylinder is a specialized hydraulic component designed to securely lock molds in industrial machinery, tailored to meet specific operational requirements like pressure, size, and durability.

Q: How to choose a reliable mold hydraulic locking cylinder factory?

A: Look for factories with ISO certification, proven industry experience, and a portfolio of custom hydraulic solutions. Ensure they offer rigorous testing and post-sales support for long-term reliability.

Q: What industries use mold hydraulic locking cylinders?

A: These cylinders are widely used in automotive, plastics injection molding, die-casting, and manufacturing industries where precision mold locking under high pressure is critical.

Q: Can a mold hydraulic locking cylinder company provide custom designs?

A: Yes, reputable companies specialize in custom designs, adapting dimensions, pressure ratings, and materials to suit unique machinery needs and ensure optimal performance.

Q: What warranties do mold hydraulic locking cylinder factories offer?

A: Leading factories typically provide 12-24 month warranties, covering defects in materials or workmanship. Extended warranties may be available for custom solutions upon request.

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025