دېكابىر . 13, 2024 20:39 Back to list

Compact Double Acting Hydraulic Cylinder for Efficient Power and Control Solutions

The Advantages and Functionality of Double Acting Hydraulic Cylinders

Hydraulic systems have become an essential part of various industrial applications, and among the key components driving these systems is the double acting hydraulic cylinder. Unlike single acting cylinders that rely solely on hydraulic pressure for one direction of movement, double acting cylinders can exert force during both the extension and retraction phases, making them incredibly versatile and efficient. In this article, we will explore the advantages, functionality, and applications of double acting hydraulic cylinders.

Structure and Operation

A double acting hydraulic cylinder consists of a cylindrical barrel, a piston, and end caps that house the seal and ports. The most distinctive feature is that it has two ports—one for extending the piston and another for retracting it. As hydraulic fluid is pumped into one side of the cylinder, pressure builds up, pushing the piston and enabling the attachment or load connected to the piston rod to move. Conversely, to retract the piston, fluid is pumped into the other port, allowing controlled movement back to the original position.

This dual-functionality allows double acting hydraulic cylinders to provide precise and efficient linear motion, and they can be engineered to handle significant loads with relative ease. They act based on Pascal's law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions, making them ideal for heavy-duty applications.

Advantages

1. Enhanced Control One of the primary advantages of double acting hydraulic cylinders is their ability to exert force in both directions, providing more control over the motion of machinery. This feature is particularly beneficial in applications that require accurate positioning.

2. Higher Efficiency Because double acting cylinders can complete work cycles in a more effective manner, they generally require less hydraulic fluid than their single acting counterparts. This efficiency can lead to lower operational costs and reduced energy consumption.

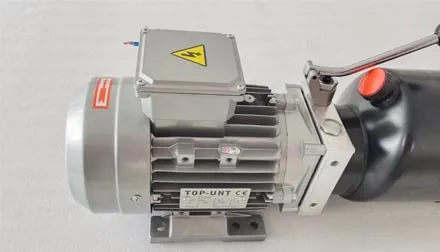

double acting hydraulic cylinder product

3. Better Load Handling Double acting hydraulic cylinders can lift heavier loads and achieve greater force output than single acting cylinders. This makes them ideal for heavy machinery used in construction, manufacturing, and other industries.

4. Compact Design The integrated functionality of the double acting cylinder allows for a more compact design, saving space in industrial setups while still providing robust performance.

5. Consistent Performance With the ability to exert force in both directions, double acting cylinders deliver consistent and reliable performance, which is essential for many industrial applications.

Applications

Double acting hydraulic cylinders have a wide range of applications across various fields. In the construction industry, they are used in excavators, loaders, and cranes for tasks such as digging, lifting, and moving heavy materials. In manufacturing, they play a vital role in pressing, stamping, and molding processes. Furthermore, they are instrumental in material handling, automotive manufacturing, and even in agriculture for equipment like tractors and harvesters.

In recent years, the demand for renewable energy solutions has also led to their use in wind turbine operations, where they help in the folding and unfolding of turbine blades.

Conclusion

The double acting hydraulic cylinder stands as a testament to the advancements in hydraulic technology, proving itself indispensable in both heavy industrial applications and precision engineering tasks. Its ability to offer enhanced control, efficiency, and load handling makes it a preferred choice in numerous sectors. Whether in construction, manufacturing, or renewable energy, double acting hydraulic cylinders continue to play a crucial role in transforming how industries operate, driving productivity, and reliability across the board. As technology progresses, we can expect further innovations in the design and functionality of these essential hydraulic components, paving the way for even greater efficiencies and capabilities in the future.

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025