Nov . 20, 2024 20:39 Back to list

rotary hydraulic cylinder manufacturer

Understanding Rotary Hydraulic Cylinder Manufacturers An Overview

In the world of industrial machinery, the rotary hydraulic cylinder plays a vital role in various applications, including construction, manufacturing, and automotive sectors. These devices harness the power of hydraulic fluid to produce rotary motion, providing high torque and precise control. With the growing demand for efficient and reliable machinery, rotary hydraulic cylinder manufacturers are stepping up to deliver innovative solutions that meet diverse industry needs.

What is a Rotary Hydraulic Cylinder?

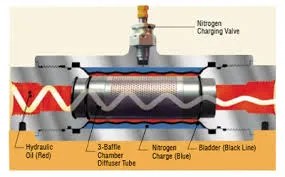

A rotary hydraulic cylinder is a type of actuator that converts hydraulic energy into rotational motion. Unlike linear hydraulic cylinders, which produce straight-line motion, rotary cylinders excel in applications where a rotating action is essential. They consist of a cylindrical housing, a rotating shaft, and internal hydraulic mechanisms that facilitate motion. Typically constructed from high-strength materials, they are designed to withstand significant loads and harsh operating conditions.

Applications of Rotary Hydraulic Cylinders

Rotary hydraulic cylinders are utilized across a variety of industries. Some common applications include

1. Construction Equipment In excavators and cranes, rotary hydraulic cylinders are used for boom rotation and other pivoting actions, allowing for improved maneuverability and efficiency. 2. Manufacturing Machinery Machinery such as lathes and milling machines rely on rotary hydraulic cylinders for precise rotation of tools and workpieces, enhancing accuracy in production.

3. Material Handling In applications like conveyor systems, these cylinders help in the rotation of handling mechanisms, ensuring the smooth flow of materials in manufacturing and logistics.

4. Automotive Industry In vehicles, rotary hydraulic cylinders are employed in steering systems and various automated processes, improving functionality and control.

Choosing a Rotary Hydraulic Cylinder Manufacturer

When selecting a rotary hydraulic cylinder manufacturer, there are several factors to consider to ensure you partner with a reliable and efficient supplier

rotary hydraulic cylinder manufacturer

1. Quality Assurance It's crucial to choose manufacturers that adhere to stringent quality control standards. Certifications such as ISO 9001 serve as an indicator of a manufacturer's commitment to quality.

2. Customization Options Different applications may require specific dimensions and capabilities. A manufacturer that offers customization can provide solutions tailored to your operational needs.

3. Technical Expertise Manufacturers with a strong engineering team can offer invaluable support, helping clients select the right cylinder for specific applications and quickly address any technical challenges.

4. After-Sales Support Effective after-sales service, including maintenance and repair support, is essential to ensure the longevity and optimal performance of hydraulic cylinders.

5. Reputation and Experience Established manufacturers with a history of reliable products and customer satisfaction are often a safer choice. Researching customer testimonials and industry reputation can provide insights into a manufacturer’s reliability.

Innovations in Rotary Hydraulic Cylinders

The rotary hydraulic cylinder industry is continually evolving, with innovations being spearheaded by forward-thinking manufacturers. Some trends include

- Smart Technology The integration of sensors and IoT (Internet of Things) capabilities allows for real-time monitoring of cylinder performance, improving efficiency and predictive maintenance. - Sustainable Practices With a growing focus on sustainability, manufacturers are exploring eco-friendly materials and processes to minimize environmental impact.

- Advanced Materials New materials that enhance strength while reducing weight can lead to improved performance and durability of hydraulic cylinders.

Conclusion

Rotary hydraulic cylinder manufacturers play a crucial role in various industrial applications, providing essential equipment that facilitates efficient operations. When choosing a manufacturer, it’s important to consider quality, customization, expertise, and after-sales support. As the industry continues to innovate, partnering with a manufacturer that embraces technological advancements and sustainability will ensure that businesses have cutting-edge solutions at their fingertips. By understanding the importance of these components and the manufacturers that produce them, companies can harness the full potential of rotary hydraulic systems, driving productivity and success in their operations.

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025