Aug . 10, 2024 02:50 Back to list

Innovative Hydraulic Downfeed Cylinder Solutions for Enhanced Performance and Efficiency in Industrial Applications

The Importance of Hydraulic Downfeed Cylinder Products in Modern Industry

In the realm of manufacturing and engineering, precision and efficiency are paramount. One of the critical components that support these principles is the hydraulic downfeed cylinder. This device plays a vital role in various applications, from metalworking to construction, ensuring that operations are executed smoothly and effectively.

Hydraulic downfeed cylinders operate on the principle of hydraulics, which utilizes pressurized liquid to generate motion. These cylinders are designed to facilitate the downward movement of tools or workpieces, contributing significantly to processes like drilling, milling, and cutting. The controlled descent allows for accurate positioning and consistent force application, which is essential in maintaining product quality and reducing waste.

One of the standout features of hydraulic downfeed cylinders is their ability to adjust the speed and force of descent. This adaptability is particularly beneficial in operations that require different levels of pressure for various materials. For instance, softer materials may require a gentler approach, while harder materials necessitate a more forceful application. Modern hydraulic downfeed cylinders often come equipped with advanced control systems that allow operators to easily modify these parameters, enhancing flexibility and productivity on the shop floor.

Another significant advantage of hydraulic downfeed cylinders is their reliability and strength. Made from high-quality materials, these cylinders are designed to withstand heavy loads and rigorous operational demands. Their robust construction means they are resistant to wear and tear, which translates to fewer breakdowns and lower maintenance costs. This durability is especially critical in high-volume production environments where downtime can lead to significant financial losses.

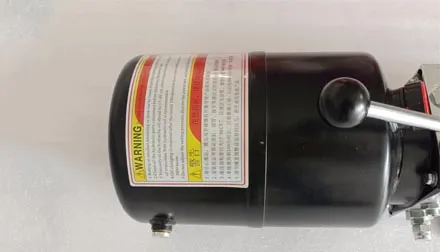

hydraulic downfeed cylinder products

Moreover, the incorporation of hydraulic downfeed cylinders is not only about enhancing performance but also improving safety in the workplace. By providing precise control over the descent of machinery, these devices help to minimize the risk of accidents that could result from uncontrolled movements. Safety features such as pressure relief valves and emergency stop mechanisms are often integrated, further ensuring that operators can work confidently and securely.

In terms of applications, hydraulic downfeed cylinders are widely utilized across various industries. In the metalworking sector, for instance, they are crucial in operating saws, shears, and presses. In woodworking, these cylinders enhance the precision of cutting and shaping machines, allowing for intricate designs and finishes. Additionally, in construction, hydraulic downfeed cylinders assist in equipment like cranes and excavators, crucial for lifting heavy materials and ensuring the smooth operation of large-scale projects.

The global market for hydraulic downfeed cylinders is continually evolving, driven by advancements in technology and the rising demand for automation. Manufacturers are increasingly focusing on developing smarter and more efficient hydraulic systems that can be seamlessly integrated into existing machinery. Innovations such as IoT-enabled cylinders, which allow for real-time monitoring and remote control, are setting new standards in operational efficiency and data-driven decision-making.

In conclusion, hydraulic downfeed cylinder products play an indispensable role in modern industrial applications. Their ability to provide precise control, reliable performance, and enhanced safety makes them a crucial component in various manufacturing processes. As industries continue to evolve and the demand for automation grows, hydraulic downfeed cylinders will undoubtedly stand at the forefront, driving efficiency and productivity while ensuring the safety and quality of operations. Investing in high-quality hydraulic downfeed cylinders is not just a necessity but a strategic move for any business aiming to thrive in today's competitive landscape.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025