Oct . 11, 2024 12:09 Back to list

center hole hydraulic cylinder manufacturer

Center Hole Hydraulic Cylinder Manufacturers An Overview

Hydraulic cylinders are critical components in many industrial applications, providing the necessary force to lift, push, or pull heavy loads. Among the various designs of hydraulic cylinders, the center hole hydraulic cylinder stands out for its unique features and applications. As industries demand more efficient and powerful hydraulic systems, the role of center hole hydraulic cylinder manufacturers becomes increasingly vital.

What is a Center Hole Hydraulic Cylinder?

A center hole hydraulic cylinder is designed with a hole in the center of the piston rod, allowing for direct passage of a hydraulic fluid. This design is particularly advantageous in applications where space is limited, and efficiency is paramount. Because the hydraulic fluid can flow through the center, it allows for smoother operations, reducing the power loss typically associated with traditional designs.

Key Features

1. Compact Design The center hole allows for a more compact design compared to standard hydraulic cylinders. This compactness makes it easier to install in tight spaces, which is often a requirement in modern machinery.

2. Increased Efficiency By allowing fluid to pass through the center, these hydraulic cylinders reduce internal resistance. This leads to higher efficiency in hydraulic systems, resulting in less energy consumption and extended operational lifespan.

3. Versatility Center hole hydraulic cylinders can be used in a variety of applications, including industrial machinery, construction equipment, and automotive systems. Their ability to handle both high and low pressure makes them suitable for diverse environments.

4. Enhanced Performance With their improved design, these cylinders provide better force output and faster response times. This performance enhancement is crucial in industries such as manufacturing, where time is of the essence.

center hole hydraulic cylinder manufacturer

Choosing the Right Manufacturer

When looking for a center hole hydraulic cylinder manufacturer, several factors come into play. Here are some key aspects to consider

1. Experience and Expertise A manufacturer’s experience in producing hydraulic cylinders can significantly affect quality. Look for companies with a proven track record in the industry.

2. Customization Options Different applications may require specific designs, materials, or features. A good manufacturer should be willing to provide customized solutions based on your requirements.

3. Quality Standards Ensure that the manufacturer adheres to international quality standards. Certifications such as ISO 9001 can serve as assurance of their commitment to quality.

4. Customer Support Reliable customer service is essential. The manufacturer should offer support in terms of installation, maintenance, and troubleshooting.

5. Reviews and Reputation Research the company’s reputation by reading customer reviews and testimonials. A reputable manufacturer is likely to have positive feedback from their clients.

Conclusion

The growth of industries reliant on hydraulic systems has created a significant demand for innovative solutions, making center hole hydraulic cylinder manufacturers crucial players in this market. With their compact design, increased efficiency, and versatility, center hole hydraulic cylinders are becoming a preferred choice across various sectors. By understanding the importance of selecting the right manufacturer, companies can ensure they receive high-quality hydraulic cylinders that meet their specific needs. As technology evolves, these manufacturers will continue to push the boundaries of hydraulic engineering, facilitating advancements that benefit all sectors of the economy.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan|Hydraulic Solutions, Customization

NewsAug.14,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|High-Precision Hydraulic Cylinder&Heavy-Duty Lifting Solution

NewsAug.14,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.14,2025

-

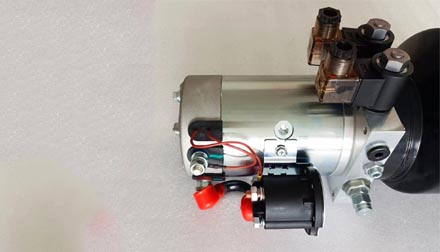

Durable Forklift Power Units for Peak Material Handling

NewsAug.14,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan Hydraulic Machinery Co., Ltd.|Industrial Lifting Solutions&Customizable Hydraulic Cylinders

NewsAug.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Hebei Shenghan

NewsAug.13,2025