Nov . 01, 2024 13:29 Back to list

Custom Hydraulic Cylinder Repair and Rebuilding Services for Enhanced Performance and Longevity

Custom Rebuild Hydraulic Cylinder Enhancing Performance and Longevity

Hydraulic cylinders are critical components in a wide array of industrial applications, serving as the driving force behind machinery used in construction, manufacturing, and transportation. Over time, these cylinders can wear out due to regular use, leading to decreased efficiency and potential safety hazards. This is where custom rebuild hydraulic cylinders come into play, offering a solution that combines repair with enhanced performance.

The custom rebuild process begins with a thorough inspection of the existing hydraulic cylinder. Technicians assess factors such as cylinder bore, rod condition, and gland integrity to determine the extent of wear and damage. This evaluation is crucial as it informs the choice of materials and components needed for the rebuild. Customization is key in this stage, as it allows for the integration of advanced materials that can provide greater resistance to wear and corrosion, ultimately prolonging the cylinder's life.

One significant advantage of opting for a custom rebuild over purchasing a new cylinder is cost efficiency. New hydraulic cylinders can be prohibitively expensive, particularly for specialized applications. A rebuild allows operators to restore functionality without the hefty price tag associated with new equipment. Moreover, many rebuild services offer quicker turnaround times than the manufacturing period for new cylinders, minimizing downtime and keeping operations running smoothly.

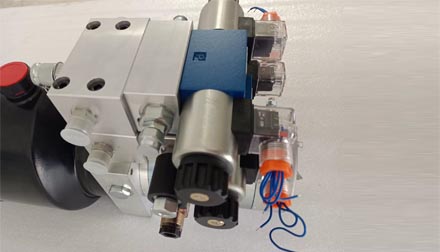

custom rebuild hydraulic cylinder

In addition to cost savings, custom rebuilt hydraulic cylinders can be tailored to suit specific operational needs, thereby improving overall system performance

. By incorporating the latest technologies and design improvements, these rebuilt cylinders can enhance responsiveness, reliability, and efficiency in hydraulic systems.Another important consideration is environmental sustainability. Rebuilding hydraulic cylinders contribute to waste reduction by extending the lifespan of existing components rather than contributing to landfill waste. This aligns with global efforts to minimize environmental impact while maintaining operational efficiency.

In summary, custom rebuild hydraulic cylinders present a compelling solution for businesses looking to restore their machinery's performance while saving on costs and supporting sustainability initiatives. By choosing to rebuild rather than replace, companies can ensure that their hydraulic systems remain efficient, reliable, and tailored to their specific needs for years to come.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025