Agosti . 20, 2024 06:55 Back to list

Hydraulic Telescopic Cylinder Manufacturing Solutions for Various Industrial Applications

The Significance of Hydraulic Telescopic Cylinder Factories

In the advanced realm of hydraulic systems, hydraulic telescopic cylinders play a crucial role in numerous applications, from construction machinery to industrial equipment. These sophisticated components are designed to offer remarkable power output and compact storage, making them indispensable in modern engineering solutions. Hydraulic telescopic cylinder factories are pivotal in this context, as they transform raw materials into essential machinery that drives various industries forward.

Understanding Hydraulic Telescopic Cylinders

A hydraulic telescopic cylinder, or telescoping cylinder, consists of multiple nested cylinders that can extend and retract, allowing for significant movement with minimal space. This design is particularly advantageous in applications requiring substantial lifting force and limited installation space. Industries such as construction, mining, and agriculture utilize these cylinders for tasks like lifting heavy loads, pushing or pulling machinery, and even in transportation systems.

The operational principle of hydraulic telescopic cylinders is rooted in fluid mechanics. By applying pressure to hydraulic fluid, the cylinders can generate significant force, translating into the mechanical movement of attached machines. This technology not only enhances efficiency but also ensures operators can handle heavy loads safely and effectively.

The Role of Factories in Production

Hydraulic telescopic cylinder factories are specialized facilities focused on the design, engineering, manufacturing, and assembly of these critical components. The production process involves several key stages, including material selection, machining, assembly, and quality control. Each stage is vital to ensuring that the final product meets stringent industry standards and customer specifications.

1. Material Selection The right materials are crucial for the durability and strength of hydraulic cylinders. Manufacturers typically use high-grade steel or aluminum alloys, leading to lighter yet robust products that can withstand high pressure.

2. Machining Precision machining is necessary to produce the intricate parts of telescopic cylinders. State-of-the-art CNC (Computer Numerical Control) machines enable factories to achieve tight tolerances and intricate designs, allowing for efficient performance and reduced wear.

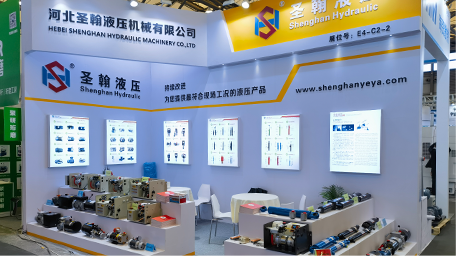

hydraulic telescopic cylinder factory

3. Assembly The assembly process must adhere to strict protocols to ensure that each cylinder functions correctly. Technicians assemble the nested cylinders, seals, and hydraulic ports, ensuring that every connection is secure and leak-free.

4. Quality Control Quality assurance is a non-negotiable aspect of hydraulic cylinder production. Factories conduct rigorous testing, including pressure tests and dimensional inspections, to verify that each cylinder meets safety standards and performance requirements before being shipped to customers.

Innovation in Design and Technology

As industries evolve, so do the demands placed on hydraulic telescopic cylinders. Factories are increasingly focusing on innovation to cater to these changing needs. Advances in material science are leading to the development of lighter and stronger materials, while improvements in hydraulic technology promise greater efficiency and reliability. Additionally, the integration of smart technology into hydraulic systems allows for improved monitoring and control, significantly enhancing operational safety.

Sustainability and Environmental Responsibility

In recent years, sustainability has become a central focus for hydraulic telescopic cylinder factories. Manufacturers are adopting environmentally friendly practices, such as reducing waste in the production process, utilizing recyclable materials, and improving energy efficiency in manufacturing operations. As industries globalize and environmental regulations become stricter, the commitment to sustainable production will become increasingly important.

Conclusion

Hydraulic telescopic cylinder factories are at the forefront of engineering solutions, playing a vital role in various sectors. By combining advanced design, precision manufacturing, and a commitment to quality, these factories produce essential components that enhance efficiency, safety, and operational capabilities across industries. As technology continues to advance, the future of hydraulic systems promises exciting innovations that will shape the landscape of mechanical engineering for years to come.

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025