Septemba . 15, 2024 02:53 Back to list

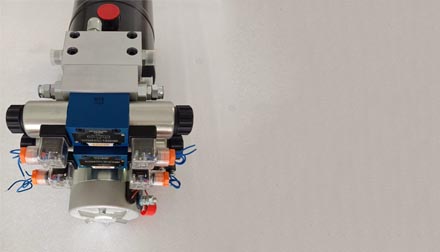

high quality hydraulic cylinder tube

High-Quality Hydraulic Cylinder Tubes A Critical Component in Modern Machinery

In the realm of industrial machinery and equipment, hydraulic systems play an indispensable role, powering everything from construction vehicles to manufacturing tools. At the heart of these systems lies the hydraulic cylinder, a critical component that converts hydraulic energy into mechanical work. One of the key factors determining the performance and longevity of a hydraulic cylinder is the quality of its tube.

Hydraulic cylinder tubes must be crafted to stringent specifications, as they are subjected to high pressures and demanding operational conditions. A high-quality tube ensures not only the effective transmission of hydraulic fluid but also the safety and reliability of the entire system. The materials used in the production of hydraulic cylinder tubes are of paramount importance. Typically, manufacturers opt for carbon steel or alloy steel due to their excellent tensile strength and resistance to wear and corrosion. These materials can withstand the intense pressures generated within hydraulic systems, while also providing a longer service life.

The manufacturing process for hydraulic cylinder tubes involves several critical steps, including precision machining and surface treatment. Precision engineering ensures that the internal diameters are smooth and free of defects, which is essential for minimizing friction and enhancing the efficiency of the hydraulic fluid flow. Surface treatment processes, such as chrome plating or hardening, help to further reinforce the tubes against wear and corrosion, ensuring durability even in harsh environments.

high quality hydraulic cylinder tube

Moreover, quality control is a pivotal aspect of producing hydraulic cylinder tubes. Rigorous testing protocols, such as pressure testing and non-destructive testing, are employed to verify the integrity and performance of the tubes. By adhering to international standards and regulations, manufacturers can guarantee that their products meet the demanding requirements of various industries, including construction, automotive, and aerospace.

Investing in high-quality hydraulic cylinder tubes not only enhances the performance of the machinery but also reduces downtime and maintenance costs

. By ensuring that hydraulic systems operate smoothly and efficiently, businesses can improve productivity and overall operational effectiveness.In conclusion, high-quality hydraulic cylinder tubes are fundamental to the reliability and efficiency of hydraulic systems. With advancements in materials and manufacturing processes, today's hydraulic cylinder tubes are more robust and versatile than ever, playing a crucial role in the success of modern machinery across various industries.

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025