Oct . 11, 2024 19:37 Back to list

hydraulic pneumatic cylinder manufacturer

Hydraulic and Pneumatic Cylinder Manufacturers An Overview

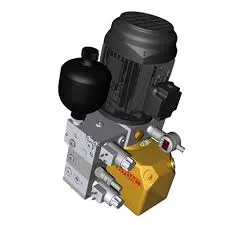

In the world of industrial automation and machinery, the significance of hydraulic and pneumatic cylinders cannot be overstated. These devices play a crucial role in the movement and control of machinery, making them integral components in various sectors, from manufacturing to aerospace. This article delves into the essence of hydraulic and pneumatic cylinders, their applications, and the significance of manufacturers in this space.

Understanding Hydraulic and Pneumatic Cylinders

Hydraulic cylinders utilize pressurized fluid to create linear motion. They are designed to lift heavy loads, operate with high force, and provide precise control. The working principle is based on Pascal’s law, which states that a change in pressure applied to an enclosed fluid is transmitted undiminished throughout the fluid. This principle makes hydraulic cylinders highly efficient for lifting and moving objects in heavy machinery, construction equipment, and more.

On the other hand, pneumatic cylinders operate on compressed air. They offer quicker actuation and are often used in applications that require rapid movement, such as in assembly lines or packaging. Pneumatics is generally cleaner and more environmentally friendly, as it does not involve hydraulic fluids that may leak and cause environmental contamination.

Both types of cylinders play critical roles in various applications like automotive assembly, robotic systems, aerospace manufacturing, and food processing. They offer the necessary force and speed required in these high-demand environments.

The Role of Manufacturers

Manufacturers of hydraulic and pneumatic cylinders are essential to the supply chain of industrial automation and machinery. They design and produce these devices to meet specific industry standards and requirements. Quality assurance and innovation are paramount in this field, as any failure in these systems can lead to significant downtime, inefficiencies, or even catastrophic accidents.

When selecting a manufacturer, several factors come into play

1. Quality Control Reputable manufacturers implement stringent quality control measures throughout the production process. This ensures that every cylinder meets the specified standards and functions reliably in demanding conditions.

hydraulic pneumatic cylinder manufacturer

2. Customization Different industries have varying requirements. Leading manufacturers offer customization options to ensure that the cylinders can fit specific machinery or operational needs. This may include varying stroke lengths, diameters, or mounting styles.

3. Technological Advancements The best manufacturers stay ahead of the curve by investing in research and development. Innovations such as smart cylinders with integrated sensors, predictive maintenance features, and energy-efficient designs are essential for modern manufacturing processes.

4. After-Sales Support Reliable manufacturers provide robust after-sales support, including maintenance services and technical assistance. This support helps companies maximize the lifespan and efficiency of their hydraulic or pneumatic systems.

5. Industry Certifications It is vital to consider manufacturers that comply with industry standards and certifications like ISO 9001. These certifications demonstrate a commitment to quality management and customer satisfaction.

The Future Landscape

As industries continue to evolve with the advent of Industry 4.0 and increased automation, the demand for advanced hydraulic and pneumatic systems is expected to rise. Manufacturers are likely to increase their focus on developing smarter, more efficient systems that can integrate with modern control technologies. This shift will help industries enhance productivity, reduce energy consumption, and improve safety.

Furthermore, as environmental concerns grow, the trend toward eco-friendly and sustainable practices will shape the future of hydraulic and pneumatic cylinder manufacturing. Manufacturers may increasingly turn to biodegradable hydraulic fluids or develop systems that use less energy and produce less waste.

Conclusion

Hydraulic and pneumatic cylinders are critical components in modern industrial applications. As the need for efficiency and precision grows, the role of manufacturers in designing and producing these devices becomes increasingly important. By focusing on quality, innovation, and customer support, manufacturers can ensure that they meet the challenges of an evolving industrial landscape. As industries strive to enhance production capabilities while minimizing their environmental footprint, hydraulic and pneumatic cylinder manufacturers will play a significant role in shaping the future of automation technologies.

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025