Nën . 18, 2024 04:50 Back to list

Hydraulic Cylinder Repair Services for Efficient Industrial Machinery Maintenance

Rebuilding Hydraulic Cylinder Companies An Essential Service for Industrial Efficiency

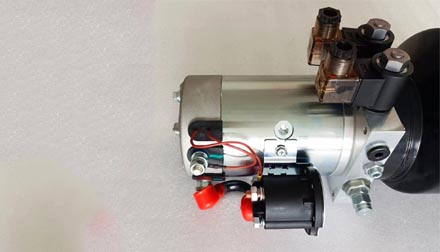

Hydraulic cylinders are crucial components in various industrial applications, providing the necessary power and motion for machinery used in construction, manufacturing, and transportation. Over time, however, these cylinders can wear out or become damaged, leading to reduced efficiency and potential failures. This is where rebuilding hydraulic cylinder companies play a vital role, offering essential services that extend the life of hydraulic systems and improve operational reliability.

Rebuilding hydraulic cylinders involves disassembling the component, inspecting for wear and damage, replacing any defective parts, and reassembling the cylinder to restore its original functionality. This process not only saves money compared to purchasing new cylinders but also minimizes environmental impact by reducing waste. Companies engaged in this service typically have specialized expertise and equipment to handle various types of hydraulic cylinders, ensuring high-quality repairs.

One of the primary advantages of working with rebuilding hydraulic cylinder companies is their ability to customize solutions based on specific needs. For instance, industries such as construction or agriculture often utilize unique hydraulic systems that require tailored rebuilding services. These companies can provide bespoke recommendations to optimize the performance of hydraulic cylinders, ensuring that they meet the operational demands of their clients. Whether it's a simple seal replacement or a complete overhaul, rebuilding companies focus on restoring cylinders to better-than-new conditions.

rebuilding hydraulic cylinder companies

Additionally, choosing to rebuild rather than replace hydraulic cylinders contributes to significant cost savings. New hydraulic cylinders can be expensive, especially for large machinery used in heavy industries. By opting for rebuilding services, companies can allocate their budget more effectively, investing in other critical areas of their operations. In many cases, rebuilding can be completed quickly, reducing downtime and allowing for a faster return to normal operations.

Furthermore, many rebuilding hydraulic cylinder companies prioritize customer service and support. They often work closely with clients to understand their specific challenges and provide ongoing maintenance recommendations. This level of service ensures that customers are not only satisfied with the immediate repairs but also equipped to prevent future issues. Regular maintenance and timely rebuilds can help extend the lifespan of hydraulic systems, ultimately leading to increased productivity and reduced operational costs.

In conclusion, rebuilding hydraulic cylinder companies play an essential role in maintaining the efficiency and reliability of industrial machinery. By offering customized solutions, significant cost savings, and exceptional customer support, these companies contribute to the sustainability and effectiveness of various industries. As businesses continue to prioritize efficiency and environmental responsibility, the importance of hydraulic cylinder rebuilding services is likely to grow, making them a critical partner in industrial operations.

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025