Oct . 21, 2024 11:30 Back to list

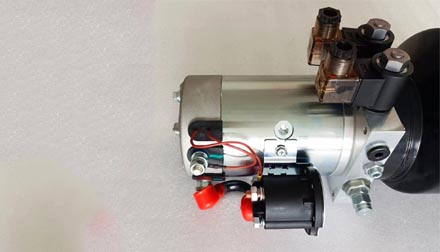

hydraulic piston cylinder product

Hydraulic Piston Cylinder Products A Comprehensive Overview

Hydraulic piston cylinder products play a crucial role in a wide range of industrial applications, serving as essential components in fluid power systems. These devices are primarily used to convert hydraulic energy into mechanical energy, providing the force needed to move heavy objects or perform complex machinery functions. Understanding the design, functionality, and applications of hydraulic piston cylinders is vital for industries that rely on precision and efficiency.

Design and Functionality

A hydraulic piston cylinder consists of a cylindrical chamber that contains a piston, which is connected to a rod. Hydraulic fluid is pumped into the chamber, causing the piston to move. This movement can be linear, rotating, or even oscillating, depending on the system's design. The primary advantage of using hydraulic systems is their ability to generate significant force with relatively small inputs of energy. The pressure generated in the hydraulic fluid can be adjusted, allowing for a versatile range of forces and speeds.

Materials used in hydraulic piston cylinders are crucial for their performance and durability. Common materials include high-strength alloys, stainless steel, and composites that endure high pressure and resist corrosion. Proper sealing mechanisms are also vital; they prevent fluid leakage and ensure the cylinder operates efficiently over long periods.

Applications Across Industries

hydraulic piston cylinder product

Hydraulic piston cylinders are utilized in countless applications, making them indispensable in various sectors. In the construction industry, they power equipment like excavators, forklifts, and bulldozers, enabling heavy lifting and precise movements on job sites. Additionally, they are integral to manufacturing processes, where they assist automation and machinery in tasks ranging from assembly to quality control.

In the automotive industry, hydraulic systems are employed for purposes such as hydraulic brakes and lift equipment. Meanwhile, the aerospace sector utilizes hydraulic systems for controlling wing flaps, landing gear, and other essential functions. Furthermore, hydraulic piston cylinders are instrumental in the agriculture sector, facilitating the operation of tractors and other farming equipment, which enhances productivity and efficiency.

Importance of Maintenance and Safety

Given their critical role, maintaining hydraulic piston cylinders is essential to ensure optimal performance and prevent unsafe conditions. Regular inspections can identify wear and tear, while timely repairs extend the life span of these components. Operators must also be aware of the safety standards and regulations governing hydraulic systems to mitigate the risks associated with high-pressure fluid environments.

Conclusion

In conclusion, hydraulic piston cylinder products are fundamental to modern engineering and industrial operations. Their design and functionality facilitate the efficient transfer of energy necessary for a myriad of applications, from construction to aerospace. As industries continue to evolve, the demand for reliable and innovative hydraulic solutions will remain robust, further solidifying the importance of hydraulic piston cylinders in our daily lives. Investing in quality products and regular maintenance will ensure these systems operate safely and efficiently, contributing to the advancement of technology and industry as a whole.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic Machinery Co., Ltd.|High-Load Capacity&Industrial Hydraulic Solution

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd. | High Performance, Durable, Industrial Use

NewsJul.21,2025