Sep . 28, 2024 12:44 Back to list

hydraulic cylinder for press companies

Hydraulic Cylinders for Press Companies A Key Component in Modern Manufacturing

In the realm of modern manufacturing, hydraulic cylinders are pivotal, especially for press companies that rely on precision and power in their operations. These devices convert hydraulic energy into mechanical force and movement, making them indispensable in various industrial applications. For press manufacturers, the importance of high-quality hydraulic cylinders cannot be overstated.

Hydraulic cylinders serve as the muscle behind many pressing operations, from metal forming to plastic molding. Their main function is to create linear motion by utilizing hydraulic fluid under pressure. When this fluid is directed into a cylinder, it pushes a piston, resulting in significant force that can be applied to various materials. This capability allows press companies to achieve high levels of accuracy and efficiency in shaping raw materials, ultimately enhancing product quality.

One of the foremost advantages of hydraulic cylinders is their ability to generate substantial force without requiring excessive physical space. This characteristic is highly valuable in press applications, as manufacturers often operate within limited confines. The press machines equipped with hydraulic cylinders can exert pressure that far exceeds the capabilities of mechanical systems, thus making them ideal for heavy-duty tasks. Moreover, the control over the hydraulic system allows for precise adjustments, leading to more consistent outcomes in manufacturing processes.

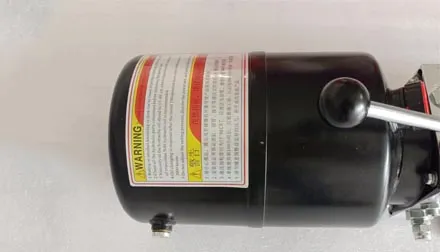

hydraulic cylinder for press companies

As industries evolve, so do the technologies behind hydraulic cylinders. Many manufacturers are now focusing on advanced materials and innovative designs to improve performance and durability. The use of composite materials and enhanced sealing technologies results in hydraulic cylinders that are not only more robust but also more efficient, reducing maintenance needs and extending lifespan. These advancements are crucial for press companies that seek to minimize downtime and maximize operational efficiency.

Environmental considerations have also influenced the design and use of hydraulic cylinders. There is an increasing emphasis on hydraulic systems that are energy-efficient and produce minimal waste. Many modern hydraulic cylinders come with features that allow for better fluid management and energy recuperation. This shift not only aligns with sustainability goals but also helps companies save on operational costs in the long run.

With the rise of automation and smart manufacturing, hydraulic cylinders are also adapting to new technologies. Integration with digital systems allows for real-time monitoring and control, facilitating predictive maintenance and better resource management. Press companies can leverage this technology to improve their operational workflows and ensure that their machines are always running at peak performance.

In conclusion, hydraulic cylinders are a fundamental element for press companies, providing the necessary force and precision to execute complex manufacturing tasks. As technology continues to advance, the importance of these hydraulic components will only grow. Press companies that invest in high-quality hydraulic cylinders will not only enhance their productivity but also position themselves favorably in an increasingly competitive market. By focusing on innovation, efficiency, and sustainability, hydraulic cylinder manufacturers and users alike can ensure they are well-equipped for the future of manufacturing.

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720: High Performance

NewsAug.18,2025