Dec . 14, 2024 14:07 Back to list

China Dual Action Hydraulic Cylinder for Efficient Industrial Applications

Understanding China’s Double Acting Cylinder Hydraulic System

The hydraulic system is an essential component of modern machinery, and among various hydraulic components, the double acting cylinder holds a prominent position. Especially in China, the development and manufacturing of double acting hydraulic cylinders have witnessed significant advancements. This article delves into the functionality, applications, and the burgeoning industry of double acting cylinder hydraulics in China.

What is a Double Acting Cylinder?

A double acting cylinder is a type of hydraulic cylinder that can apply force in both extension and retraction strokes. Unlike single acting cylinders, which only use hydraulic power for one direction, double acting cylinders employ hydraulic pressure for both movements. This design allows for greater efficiency and power, making it suitable for various heavy-duty applications.

The basic operation of a double acting cylinder involves the movement of hydraulic fluid. When the hydraulic fluid is pumped into one chamber of the cylinder, it causes the piston within to move in one direction, generating force. Reversing the flow of the hydraulic fluid allows the piston to move back, thus completing a full cycle. This bidirectional action enables smoother and more efficient operation in various equipment and machinery.

Applications in Industry

The applications of double acting cylinders are vast and diverse. In the manufacturing sector, they are used in automated assembly lines, CNC machines, and various fabrication processes. The construction industry relies on double acting cylinders for excavators, loaders, and cranes, where robust lifting capabilities are crucial.

Moreover, the automotive sector employs these hydraulic systems for car lifts, presses, and other machinery essential for both production and maintenance

. In the agricultural field, double acting cylinders power various equipment like tractors and harvesters, facilitating tasks such as plowing and lifting heavy loads.china double acting cylinder hydraulic

The Chinese Market

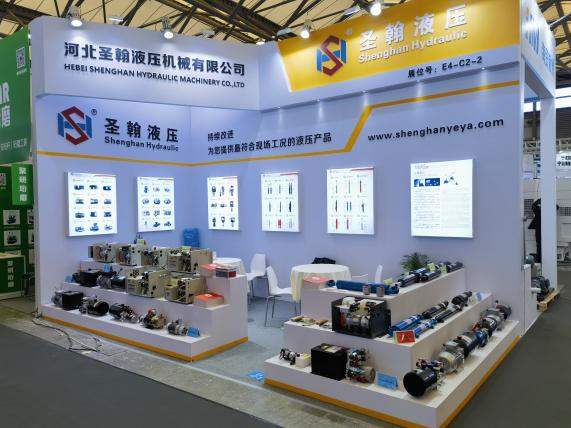

China has become a global leader in the manufacturing of double acting hydraulic cylinders. The rapid industrialization and growth of infrastructure projects in the country have significantly boosted the demand for hydraulic systems. Local manufacturers are continuously innovating and improving their production techniques to enhance efficiency and meet international standards.

Chinese companies are now producing a wide range of hydraulic cylinders, tailored to suit specific industry needs. Many firms emphasize quality and reliability, ensuring that their products can withstand the demanding conditions of industrial usage. Moreover, as environmental concerns grow, some manufacturers are exploring eco-friendly hydraulic fluids and materials, contributing to sustainable practices within the industry.

Technological Advancements

In recent years, significant technological advancements have revolutionized the design and functionality of double acting cylinders. Innovations such as advanced sealing technologies, improved materials, and sophisticated control systems are enhancing the overall performance and lifespan of these hydraulic components.

The integration of smart technologies is also becoming increasingly prevalent. Sensors and control systems now allow for real-time monitoring and adjustments, leading to greater precision in applications. This level of automation not only improves productivity but also reduces the chances of mechanical failure, further solidifying the importance of double acting cylinders in modern automation.

Conclusion

The double acting cylinder hydraulic system plays a pivotal role in various industries, particularly in China, where the demand for powerful and efficient machinery is ever-growing. As the country continues to lead in manufacturing and technological innovations, the future of double acting hydraulic cylinders looks promising. With ongoing advancements and a commitment to quality, Chinese manufacturers are positioned to meet both domestic and international needs, reinforcing their significance in the global hydraulic market.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.17,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.|Precision Engineering,Customization Options

NewsAug.17,2025

-

Efficient Double Acting Power Unit | Versatile Hydraulic Systems

NewsAug.17,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic|Heavy-Duty Lifting,Custom Hydraulic Solutions

NewsAug.17,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co. Ltd.

NewsAug.16,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Industrial Lifting, Custom Hydraulic Systems

NewsAug.16,2025