Nov . 27, 2024 23:55 Back to list

Measuring Techniques for Hydraulic Cylinders in Chinese Industries

Measuring a Hydraulic Cylinder in China A Comprehensive Guide

Hydraulic cylinders are vital components in various industrial applications, particularly in construction machinery, manufacturing equipment, and aerospace technology. In China, where manufacturing and technological developments are rapidly advancing, accurately measuring hydraulic cylinders is crucial for ensuring efficiency, safety, and quality. This article will delve into the significance of measuring hydraulic cylinders, the methods employed in China, and the challenges faced in this process.

The Importance of Accurate Measurement

Accurate measurement of hydraulic cylinders is essential for several reasons. Firstly, precise dimensions ensure that the cylinder can fit correctly within the machine it is designed for, avoiding operational issues. Secondly, maintaining tolerances is vital for performance; hydraulic cylinders operate under high pressure, and any deviation can lead to malfunction or failure. This can cause safety hazards and significant financial losses. Additionally, accuracy in measurement affects the longevity and maintenance schedules for hydraulic systems.

In the competitive landscape of manufacturing in China, where there is a strong push for quality control, ensuring that hydraulic cylinders meet specifications directly impacts operational efficiency and product reliability. This is especially relevant given China's role as a global supplier of machinery and industrial equipment.

Methods of Measurement

In China, various methods are used to measure hydraulic cylinders precisely

. The choice of technique often depends on the specific requirements of the application and the available technology.1. Traditional Measurement Techniques This includes using calipers, micrometers, and gauges to measure the external and internal dimensions of hydraulic cylinders. These tools are still commonly used, especially for smaller workshops that may not have access to advanced technology.

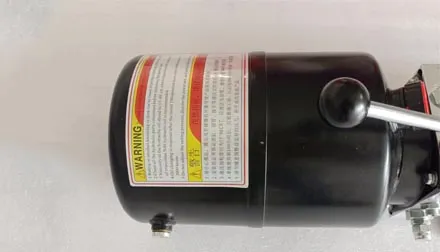

china measuring a hydraulic cylinder

2. Laser Measurement Systems With the advancement of technology, laser measurement systems have gained popularity in China. These systems allow for non-contact measurement, providing high precision and accuracy. They can measure the cylindrical shape and detect any surface imperfections, which is crucial for the performance of hydraulic cylinders.

3. Coordinate Measuring Machines (CMM) CMMs are sophisticated devices that can measure the physical geometrical characteristics of an object. They can be operated manually or controlled via computer, offering exceptional accuracy. In large manufacturing settings in China, CMMs are routinely used to ensure that every hydraulic cylinder meets stringent quality standards.

4. 3D Scanning As industries embrace the digital revolution, 3D scanning technology is becoming more prevalent. This method allows for the creation of a digital model of the hydraulic cylinder, which can be analyzed for dimensional accuracy. This is particularly useful for complex or custom-designed cylinders that require precise specifications.

Challenges in Measurement

Even with advanced technologies, challenges remain in measuring hydraulic cylinders accurately. One significant challenge is variability in materials. Hydraulic cylinders can be manufactured from different metals and polymers, each with unique properties that can affect measurement. For instance, temperature fluctuations can cause materials to expand or contract, impacting the accuracy of measurements.

Moreover, the intricacies of design can present difficulties. Hydraulic cylinders often have unique shapes and internal components that require complex measurement strategies. Ensuring that these components are correctly measured without impacting their functionality is a delicate balance.

Conclusion

In conclusion, measuring hydraulic cylinders is a critical aspect of maintaining quality and efficiency in China's fast-paced industrial environment. The methods employed range from traditional tools to advanced technologies like laser measurement systems and 3D scanning, each having its advantages and drawbacks. Despite the challenges associated with variability in materials and design intricacies, the commitment to precision measurement remains a cornerstone of China's manufacturing ethos. As industries continue to evolve and technology progresses, the importance of accurate measurement will only grow, solidifying China's position as a leader in global manufacturing.

-

Pallet Truck Power Units: Smart Logistics Solutions

NewsAug.01,2025

-

1.5 Ton Lifting Cylinder - Hebei Shenghan | Heavy-Duty Hydraulic Solutions

NewsAug.01,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Heavy-Duty Lifting, Precision Engineering

NewsAug.01,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Lifting Solutions

NewsAug.01,2025

-

Double Acting Power Unit with GPT-4 Turbo | AI Hydraulics

NewsJul.31,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan Hydraulic|Heavy-Duty Lifting,Custom Hydraulic Solutions

NewsJul.30,2025