Дек . 12, 2024 10:55 Back to list

single line hydraulic cylinder factory

The Essence of Single Line Hydraulic Cylinder Manufacturing

In the modern industrial landscape, hydraulic systems play a crucial role in powering machinery and equipment across various sectors. Among the most pivotal components of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical motion. Specifically, single line hydraulic cylinders serve as a key technology in numerous applications, exemplifying efficiency and compact design. This article will delve into the significance of single line hydraulic cylinder manufacturing, highlighting their functionality, applications, and the intricacies involved in their production.

Understanding Single Line Hydraulic Cylinders

At the core of a single line hydraulic cylinder is its simplicity and effectiveness. Unlike traditional hydraulic cylinders that require multiple lines for operation, single line hydraulic cylinders operate using a single line to control the fluid flow. This design reduces complexity, minimizes potential points of failure, and enhances the overall performance of hydraulic systems. The cylinder’s operation involves a single port for both fluid input and output, streamlining the design while maintaining high efficiency.

As hydraulic fluid enters the cylinder through the single line, it creates pressure that pushes the piston, resulting in linear motion. This linear motion can then be harnessed to perform various types of work, from lifting heavy loads to powering machinery. The innovative design of single line hydraulic cylinders allows for quick actuation and efficient power transmission, making them ideal for various industrial applications.

Applications Across Industries

Single line hydraulic cylinders find utility in a wide range of sectors. In construction, they are commonly used in excavators, bulldozers, and other heavy machinery, providing the necessary force to lift and move tons of material. In manufacturing, they play a vital role in automated production lines, facilitating tasks such as assembly, packaging, and material handling. Agricultural machinery also benefits from these cylinders, enhancing the efficiency of equipment like tractors and harvesters.

Moreover, the automotive industry utilizes single line hydraulic cylinders in vehicle lifts and other equipment where space and simplicity are critical. Their lightweight design and robust performance make them an excellent choice for enhancing operational efficiency. As industries continue to evolve and demand for effective hydraulic solutions increases, the versatility of single line hydraulic cylinders guarantees their sustained relevance.

single line hydraulic cylinder factory

The Manufacturing Process

The manufacturing process of single line hydraulic cylinders involves several critical stages, each of which ensures the final product meets stringent quality and performance standards. Initially, high-grade materials such as steel or aluminum are selected to ensure durability and resistance to wear and pressure. The choice of materials is paramount, as hydraulic cylinders operate under significant stress and require materials that can withstand harsh operating conditions.

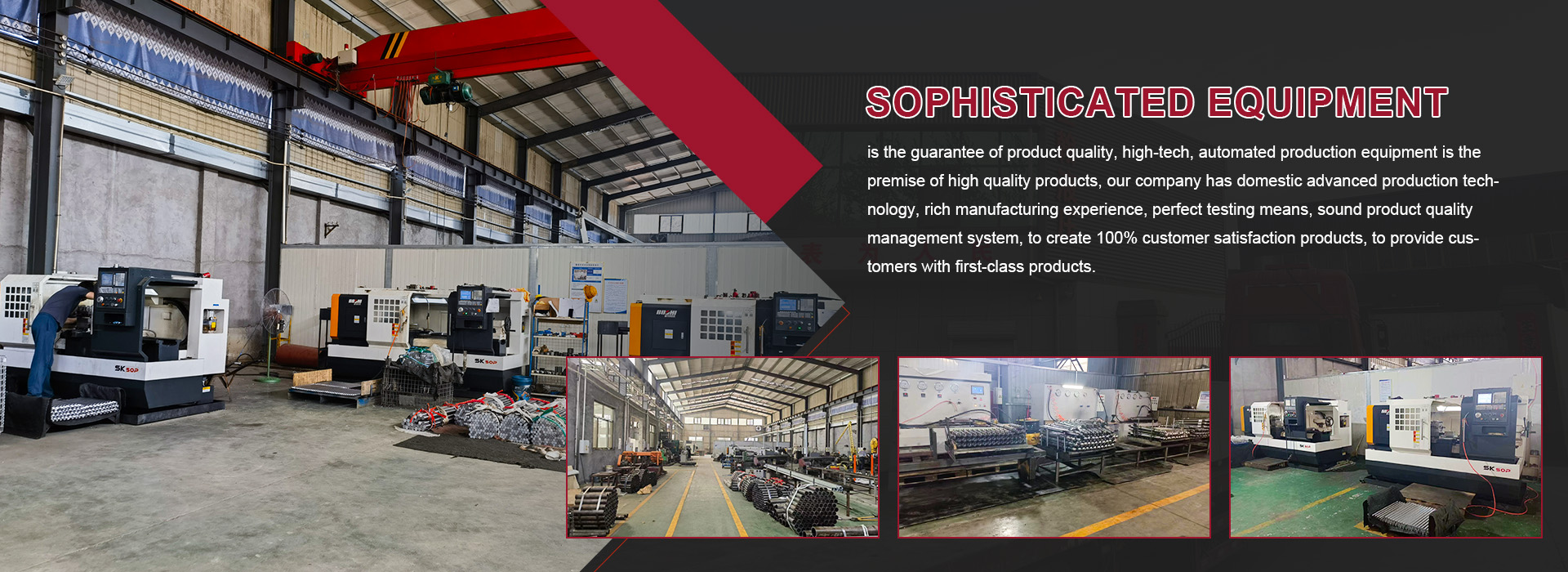

Following material selection, the manufacturing process begins with machining components to exact specifications. Precision machining is vital to ensure that each cylinder is built to handle the specific pressures it will encounter. Additionally, the production process integrates cutting-edge technology such as CNC (Computer Numerical Control) machining, which enhances accuracy and consistency in manufacturing.

After machining, the components undergo rigorous testing to ensure that they function correctly under different conditions. This quality control phase includes pressure tests, dimensional checks, and performance assessments. Only components that meet the required standards proceed to assembly. Skilled technicians meticulously assemble the cylinders, ensuring that seals and connections are tight to prevent leaks and maximize efficiency.

Finally, once assembled, the hydraulic cylinders receive a finishing treatment, such as painting or coating, which protects them from corrosion and enhances their aesthetics. The final products are then packaged and shipped, ensuring they reach customers in pristine condition.

Conclusion

The manufacturing of single line hydraulic cylinders showcases the intersection of innovation and practicality. Their ability to deliver powerful performance in a compact design makes them indispensable across industries. As global industries continue to seek efficient and reliable hydraulic solutions, the role of single line hydraulic cylinders will only grow in importance. With advancements in technology and manufacturing processes, we can anticipate even greater improvements in their performance and application in the years to come. In this evolved landscape of hydraulic technology, single line hydraulic cylinder factories stand as beacons of efficiency and progress, contributing significantly to the momentum of industrial advancement.

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535|Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720: High Performance

NewsAug.18,2025