ian. . 01, 2025 09:43 Back to list

Custom Hydraulic Cylinder Fittings for Optimal Performance and Efficiency Solutions

Custom Hydraulic Cylinder Fittings Enhancing Efficiency and Performance

In various industries, from manufacturing to automotive, hydraulic systems play a crucial role in ensuring operational efficiency. At the heart of these systems are hydraulic cylinders, which convert hydraulic energy into mechanical force. However, the effectiveness of these cylinders largely depends on the quality and compatibility of their fittings. Custom hydraulic cylinder fittings have emerged as a vital component in maximizing performance and ensuring seamless functionality.

The Importance of Customization

Every hydraulic application has its unique requirements. Standard fittings may not always meet the specific demands of specialized machinery or equipment. Custom fittings allow engineers and designers to tailor solutions that perfectly match the specifications of a given hydraulic system. This customized approach ensures optimal fluid flow, pressure, and overall performance.

Customization can cover a wide array of features, including size, shape, material, and connection type. By designing fittings that fit precisely with hydraulic cylinders, companies can minimize the risk of leaks and ensure that systems operate at peak efficiency. Moreover, custom fittings can enhance the lifespan of hydraulic components, reducing maintenance needs and operational downtime.

Design and Material Considerations

When creating custom hydraulic cylinder fittings, several design and material factors must be considered. The choice of material is paramount; steel, aluminum, and various alloys are commonly used based on the application’s pressure requirements and environmental conditions. For example, stainless steel fittings offer superior corrosion resistance, making them ideal for applications in harsh environments or in industries where hygiene is paramount, such as food processing.

Furthermore, designing fittings to accommodate various connection types—such as threaded, flanged, or quick-connect styles—ensures broader compatibility with existing systems. This flexibility can be especially beneficial in retrofitting older equipment or integrating new technology into existing machines.

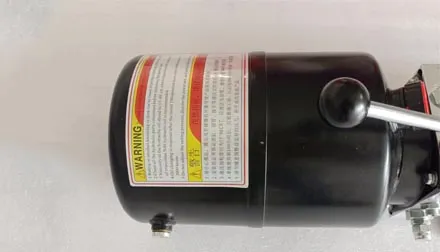

custom hydraulic cylinder fittings

Enhancing Efficiency and Safety

Using custom hydraulic cylinder fittings not only boosts efficiency but also enhances safety. Properly designed and fitted hydraulic components reduce the likelihood of leaks, which can lead to hazardous situations. For instance, hydraulic fluid leaks can create slip hazards, environmental concerns, and even product contamination. By ensuring a tight, secure fit, custom fittings contribute to a safer working environment.

Additionally, efficient hydraulic systems reduce energy consumption. When fittings are matched precisely to their respective cylinders, they reduce friction and resistance, allowing for smoother operation of hydraulic machinery. This efficiency translates to lower operational costs and increased productivity—an essential factor in today’s competitive industrial landscape.

The Role of Innovation and Technology

The advancement of technology has revolutionized the creation of custom hydraulic fittings. Modern CAD (Computer-Aided Design) software enables engineers to create precise 3D models of fittings, facilitating rigorous testing and simulation before manufacturing. Additive manufacturing techniques, such as 3D printing, allow for rapid prototyping and adjustments, ensuring that the final product meets all performance specifications.

Moreover, the integration of smart technology into hydraulic systems is providing new opportunities for customization. Sensors and IoT (Internet of Things) devices can monitor system performance in real time, providing data that can inform further design modifications and enhancements.

Conclusion

Custom hydraulic cylinder fittings are essential for optimizing the performance and reliability of hydraulic systems across various industries. By investing in tailored solutions, businesses can enhance efficiency, improve safety, and reduce maintenance costs. As technology continues to evolve, the potential for innovation in the design and manufacturing of these fittings remains vast. Companies that leverage custom fittings will not only gain a competitive edge but also contribute to the advancement of hydraulic technology in an increasingly demanding market. The future of hydraulic systems is undeniably tied to the precision, safety, and efficiency provided by custom fittings, making their significance crucial in driving industrial success.

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025