ਅਕਤੂਃ . 04, 2024 15:17 Back to list

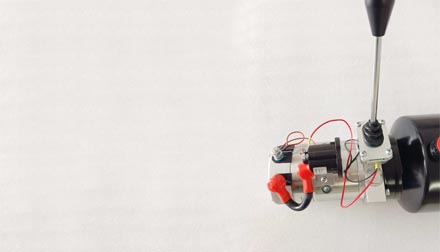

single hose hydraulic cylinder manufacturers

Exploring the World of Single Hose Hydraulic Cylinder Manufacturers

Hydraulic cylinders are integral components in a wide range of machinery and equipment, serving crucial roles in various industrial applications. Among the many types available, single hose hydraulic cylinders stand out due to their efficiency and simplicity. This article delves into the key aspects of single hose hydraulic cylinder manufacturers, highlighting their significance in the hydraulic systems landscape.

Understanding Single Hose Hydraulic Cylinders

Single hose hydraulic cylinders operate based on the principle of hydraulic pressure. They typically consist of a cylinder barrel, a piston, and a rod, with the unique feature of having a single hose connecting to the hydraulic fluid source. This design allows for a streamlined flow of hydraulic fluid, resulting in more efficient operation, reduced potential for leaks, and lower maintenance needs compared to traditional dual-hose systems.

The Role of Manufacturers

Manufacturers of single hose hydraulic cylinders play a pivotal role in ensuring the production of these vital components meets industry standards. They are responsible for the design, fabrication, testing, and distribution of hydraulic cylinders. High-quality manufacturing practices are essential to ensure the durability and reliability of these components, which are often subjected to extreme pressures and conditions.

Key Features to Look for in Manufacturers

When selecting a manufacturer for single hose hydraulic cylinders, several factors should be considered

single hose hydraulic cylinder manufacturers

1. Industry Experience An experienced manufacturer will possess in-depth knowledge of hydraulic systems and can offer expert guidance on choosing the right cylinder for specific applications.

2. Quality Assurance A commitment to quality is paramount. Look for manufacturers that adhere to international standards, such as ISO certification, and have rigorous testing procedures in place.

3. Customization Options Different applications may require unique specifications. Reputable manufacturers should offer customization options to cater to specific needs, including size, material, and pressure ratings.

4. Material Selection The choice of materials used in the construction of hydraulic cylinders greatly affects their performance and longevity. Leading manufacturers utilize high-grade materials that withstand corrosion and wear.

5. After-Sales Support Reliable customer service and support after the purchase are essential. A manufacturer that provides effective after-sales assistance can help ensure that any issues are promptly addressed, enhancing the overall user experience.

The Future of Single Hose Hydraulic Cylinder Manufacturing

As industries continue to evolve, the demand for more efficient and reliable hydraulic systems is growing. Manufacturers are innovating by incorporating advanced technologies such as automation, which enhances production efficiency and consistency. Moreover, the shift toward sustainability is prompting manufacturers to explore eco-friendly materials and production methods, aligning with global efforts to reduce environmental impact.

In conclusion, single hose hydraulic cylinder manufacturers play a crucial role in the machinery and equipment industries. By understanding the key features of these manufacturers and recognizing the importance of quality and innovation, businesses can ensure they select the right partners to meet their hydraulic system needs. As the industry continues to advance, these manufacturers will be at the forefront of providing essential solutions that drive efficiency and productivity across various sectors.

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025