Nov . 13, 2024 17:02 Back to list

head trunnion hydraulic cylinder company

Exploring the Innovations in Head Trunnion Hydraulic Cylinder Manufacturing

In the dynamic field of industrial hydraulics, the role of head trunnion hydraulic cylinders is significant. These specialized components are integral to various applications, particularly in the sectors of construction, mining, and heavy machinery. The precise engineering and innovation behind these cylinders form the backbone of their efficiency and reliability. As we delve deep into the realm of head trunnion hydraulic cylinder manufacturing, we uncover the trends, technologies, and future directions of this vital industry.

Overview of Head Trunnion Hydraulic Cylinders

A head trunnion hydraulic cylinder is designed to support and control heavy equipment movements, enabling operators to achieve precision and control in demanding environments. These cylinders are typically mounted on a trunnion, which provides a stable pivot point, allowing for a wide range of motion. Their robust construction is essential for withstanding high-pressure systems while maintaining operational efficiency.

These cylinders are commonly used in applications such as the movement of cranes, the lifting of heavy loads, and the tilting of equipment in mining operations. This versatility makes them a critical component in ensuring operational success across multiple industries.

Manufacturing Innovations

The manufacturing of head trunnion hydraulic cylinders has evolved significantly over the years, with advancements in materials, design, and production techniques. Modern manufacturers utilize advanced materials such as high-tensile steel and composites that enhance the durability and performance of hydraulic cylinders. This shift not only improves the lifespan of the product but also boosts its efficiency under extreme conditions.

Additionally, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has streamlined the design process, allowing engineers to simulate and optimize performance before the actual manufacturing begins. This technological progression results in more precise and reliable products, satisfying the high standards demanded by the industry.

Quality Control and Testing

head trunnion hydraulic cylinder company

In the production of head trunnion hydraulic cylinders, quality control is paramount. Manufacturers employ rigorous testing protocols to ensure that each cylinder meets strict safety and performance standards. This includes hydrostatic testing, where the cylinders are subjected to high-pressure water to identify any potential leaks or failures.

Furthermore, non-destructive testing (NDT) methods such as ultrasonic or magnetic particle inspections are used to examine the internal structure of the cylinders, ensuring there are no hidden defects. By maintaining an unwavering commitment to quality, manufacturers can guarantee a product that not only meets but exceeds industry expectations.

Environmental Considerations

As environmental awareness grows, the hydraulic cylinder manufacturing industry is also responding with sustainable practices. Companies are increasingly focusing on reducing waste during production, recycling materials, and using eco-friendly lubricants in their hydraulic systems. This shift not only helps in minimizing the environmental impact but also appeals to a growing customer base that prioritizes sustainability in their business operations.

Future Directions

Looking to the future, the head trunnion hydraulic cylinder market is poised for growth. The ongoing advancements in automation and smart technology are set to revolutionize hydraulic systems. Manufacturers are exploring the integration of IoT (Internet of Things) technology to enable real-time monitoring and predictive maintenance of hydraulic cylinders, thereby increasing efficiency and reducing downtime.

Moreover, the demand for enhanced performance in extreme conditions is driving innovation in cylinder design. Research into alternative materials, such as lightweight alloys and advanced composites, continues to unfold, with the potential to yield even greater efficiency and durability.

Conclusion

The head trunnion hydraulic cylinder manufacturing industry is a testament to the power of innovation and quality engineering. As trends like automation and sustainability take root, manufacturers are adapting to meet the changing needs of the market while maintaining a strong focus on quality and performance. In a world where precision and reliability are paramount, head trunnion hydraulic cylinders will continue to play a crucial role in driving industries forward, ensuring that they can meet the challenges of tomorrow with confidence.

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

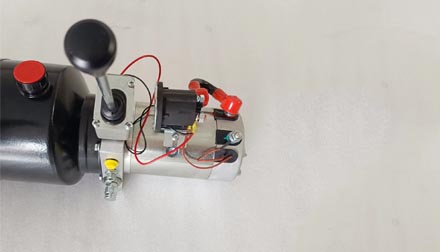

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025

-

Efficient & Reliable Double Acting Power Unit | Hydraulic Solutions

NewsAug.23,2025

-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025