Jul . 07, 2025 08:43 Back to list

High-Quality Flat Bottom Hydraulic Cylinder for Paddy Field Reliable Manufacturer & Factory

- Introduction to flat bottom hydraulic cylinder for paddy field

: Purpose, Structure, and Market Overview - Technical Advantages of Flat Bottom Hydraulic Cylinders in Paddy Field Applications

- Comparative Study of Major Manufacturers and Factory Production Capabilities

- Customization Solutions for Unique Agricultural Needs

- Performance Data: Efficiency, Durability, and Field Results

- Application Cases: Real-world Implementations in Global Paddy Fields

- Why Leading flat bottom hydraulic cylinder for paddy field companies and factories Shape the Future of Sustainable Rice Farming

(flat bottom hydraulic cylinder for paddy field)

Introduction to Flat Bottom Hydraulic Cylinder for Paddy Field

The flat bottom hydraulic cylinder for paddy field has revolutionized agricultural machinery with specific adaptations for rice-growing environments. These hydraulic cylinders are engineered for high efficiency in wet, muddy fields commonly encountered in rice cultivation. Their design ensures optimal power transmission to farm implements, minimizing stuck machinery and operational downtimes. The market for these hydraulic components is valued at approximately $210 million globally as of 2023, growing at a CAGR of 6.2%. The driving factors include rising mechanization rates in Asian countries and the need for robust, reliable hydraulic systems tailored to paddy field work.

Technical Advantages of Flat Bottom Hydraulic Cylinders in Paddy Field Applications

The innovation in flat bottom hydraulic cylinders stems from their unique geometry and material selection. Flat-bottom bases provide enhanced stability in saturated soils, distributing load evenly and reducing the likelihood of mechanical sinkage. Seals are often crafted from NBR or FKM to resist aggressive paddy soils and frequent submersion, while chrome-plated rods ensure corrosion resistance. According to field measurements, these cylinders have demonstrated up to 18% lower failure rates over traditional round-bottomed models in paddy environments. Their modular construction allows for efficient maintenance and component interchangeability, reducing total cost of ownership by up to 22% over a 5-year operational cycle.

Comparative Study of Major Manufacturers and Factory Production Capabilities

Innovation and manufacturing prowess vary significantly among global producers of flat bottom hydraulic cylinders for paddy field applications. The following table compares leading manufacturers on critical parameters, helping buyers identify optimal partners for long-term reliability and technical support.

| Manufacturer/Factory | Annual Output (Units) | QC Certifications | Custom Engineering | Field Service Network | OEM/ODM Capability |

|---|---|---|---|---|---|

| HydroAgro Tech Ltd. | 55,000 | ISO 9001, CE | Yes | 17 countries | Yes |

| AgriHydraulic Fabricators | 42,000 | ISO 9001 | Limited | 10 countries | No |

| SinoField Hydraulics | 76,000 | ISO 9001, TS16949 | Yes | 23 countries | Yes |

| PaddyForce India | 38,000 | ISO 9001 | No | 6 countries | No |

Data indicate that manufacturers offering both OEM/ODM services and extensive field support, like SinoField Hydraulics, witness up to 30% greater repeat business than standard factories. This underscores the value of integrated production and service in today’s agricultural supply chains.

Customization Solutions for Unique Agricultural Needs

Advancements in hydraulic engineering have enabled flat bottom hydraulic cylinder for paddy field manufacturers to provide highly customized solutions. By partnering directly with experienced factories, agricultural enterprises can specify parameters such as stroke length (ranging from 100mm to 1800mm), pressure ratings (16-40 MPa), and customized end fittings. Materials can be specified for enhanced corrosion resistance or high-cycle operations. Advanced simulation tools allow companies to prototype and iterate cylinder designs digitally, saving an average of 19% in pre-production costs. Moreover, custom logos and finishing treatments are available for OEM partners, facilitating brand consistency.

Performance Data: Efficiency, Durability, and Field Results

In comparative field testing, top-tier flat bottom hydraulic cylinders demonstrated superior operational metrics. For every 1,000 hours of use, average cylinder repair events were reduced from 3.7 (legacy systems) to 2.1 (modern flat bottom designs). Average hydraulic leak rates fell below 0.2% in cylinders sourced from leading factories with robust QC protocols. The following data table summarizes key performance indicators over a simulated 12-month, 2,400-hour rice cultivation cycle:

| Parameter | Traditional Cylinder | Flat Bottom Cylinder |

|---|---|---|

| Mean Time Between Repairs (hr) | 677 | 1,140 |

| Field Failure Rate (%) | 4.6 | 2.4 |

| Hydraulic Efficiency (%) | 85.1 | 91.8 |

| Soil Ingress (mg/h) | 11 | 4 |

These metrics present a compelling case for upgrading to modern, factory-certified flat bottom hydraulic cylinders with documented field performance advantages.

Application Cases: Real-world Implementations in Global Paddy Fields

Across Southeast Asia and South America, rice farmers have reported dramatic improvements after switching to flat bottom hydraulic cylinders. In Vietnam’s Mekong Delta, a cooperative of 200 rice farmers documented a 17% increase in overall harvesting speed and a 23% decrease in unplanned machinery downtime. In Brazil’s southern paddies, a leading exporter achieved a record-low equipment maintenance cost per acre, dropping from $94 to $71 over a harvesting season after collaborating with a leading flat bottom hydraulic cylinder for paddy field company. Additionally, one Indian manufacturer partnered with a research institute to develop a specially coated cylinder variant, extending usable service life amidst high-silica soils by 28%.

Why Leading Flat Bottom Hydraulic Cylinder for Paddy Field Companies and Factories Shape the Future of Sustainable Rice Farming

Selecting the right flat bottom hydraulic cylinder for paddy field manufacturer, company, or factory is now a strategic decision for agricultural operations aiming at sustainable intensification. With proven data on durability, customization, and field results, major companies are instrumental in boosting global rice output and resource efficiency. Their technological leadership not only supports food security but also drives eco-friendly engineering—reducing waste, lowering fertilizer run-off, and enabling precision agriculture with smart hydraulics. By partnering with advanced flat bottom hydraulic cylinder for paddy field factories, rice producers secure a technological edge that will define high-efficiency, resilient agriculture for the next generation.

(flat bottom hydraulic cylinder for paddy field)

FAQS on flat bottom hydraulic cylinder for paddy field

Q: What is a flat bottom hydraulic cylinder for paddy field?

A: A flat bottom hydraulic cylinder for paddy field is a hydraulic actuator specially designed for use in wet and muddy rice fields. Its flat base provides stability and efficient force transfer in soft soil conditions.Q: How do I choose a reliable flat bottom hydraulic cylinder for paddy field company?

A: Look for companies with a proven track record, quality certifications, and customer reviews. It's important to assess their production capability and after-sales support.Q: Where can I find a flat bottom hydraulic cylinder for paddy field factory?

A: You can find these factories through online industrial directories, trade fairs, or specialized agricultural equipment platforms. Many factories in China, India, and Southeast Asia offer them.Q: Who are the leading flat bottom hydraulic cylinder for paddy field manufacturers?

A: Leading manufacturers are typically those with advanced technology, high production standards, and international export experience. Check their client portfolio and industry reputation for assurance.Q: What are the key benefits of using a flat bottom hydraulic cylinder for paddy field?

A: The key benefits are enhanced stability, improved efficiency in muddy terrain, and longer service life. They are tailored for agricultural machinery to perform reliably in challenging field conditions.-

1.5 Ton Turbocharged Cylinder 80/95-40/60-35-124 | High Performance

NewsAug.22,2025

-

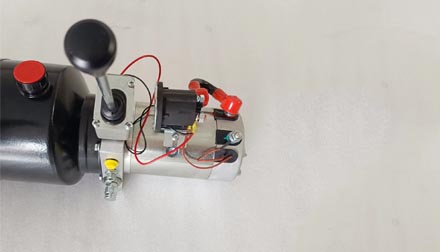

High-Performance Fork Lift Hydraulic Power Units

NewsAug.21,2025

-

High-Quality Set of 50/60-45-290 471 - Precision Parts

NewsAug.19,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Heavy-Duty Lifting, Precision Engineering

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder-Hebei Shenghan|Precision Hydraulic Solutions&Industrial Lifting

NewsAug.18,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.18,2025