nov . 01, 2024 12:29 Back to list

Top Manufacturers of Single Hydraulic Cylinders for Various Applications

The Role of Single Hydraulic Cylinder Manufacturers in Modern Industry

In an era characterized by rapid technological advancements and increasing demand for efficient machinery, single hydraulic cylinders have emerged as pivotal components across various industrial applications. Manufacturers specializing in these hydraulic solutions play a critical role by providing robust, reliable, and precise components essential for the performance and efficiency of machinery.

Understanding Single Hydraulic Cylinders

Single hydraulic cylinders are devices that convert hydraulic energy into mechanical force and motion. Comprising a cylinder, piston, and hydraulic fluid, these systems operate by utilizing pressurized fluids to move the piston within the cylinder. This movement can then be harnessed to perform various tasks, from lifting heavy loads to controlling equipment in manufacturing processes. Their simplicity and effectiveness make them indispensable in sectors such as construction, automotive, aerospace, and manufacturing.

Importance of Manufacturers

The quality and durability of hydraulic cylinders are paramount for the safety and efficiency of machinery. This is where single hydraulic cylinder manufacturers come into play. These manufacturers not only produce standard models but also offer customized solutions tailored to the specific needs of clients. By leveraging advanced materials and cutting-edge manufacturing techniques, they ensure that their products can withstand the rigors of demanding environments.

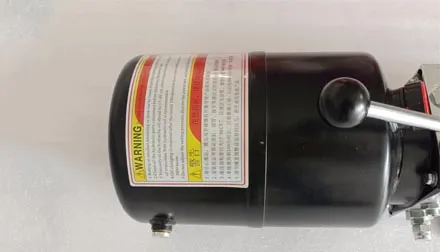

single hydraulic cylinder manufacturers

One of the key responsibilities of these manufacturers is to adhere to strict industry standards and regulations. Compliance ensures that the hydraulic cylinders operate safely and efficiently, minimizing the risk of failure and accidents. Additionally, many manufacturers invest in research and development to innovate new designs that enhance performance, improve energy efficiency, and reduce the environmental impact.

Technological Advancements

As technology continues to evolve, so does the landscape of hydraulic cylinder manufacturing. Incorporating smart technology into hydraulic systems is a growing trend. Manufacturers are increasingly integrating sensors and IoT (Internet of Things) capabilities into single hydraulic cylinders, enabling real-time monitoring and data analysis. This innovation not only enhances performance but also allows for predictive maintenance, significantly reducing downtime and maintenance costs.

Furthermore, the use of advanced materials, such as high-strength alloys and composite materials, has improved the performance and longevity of hydraulic cylinders. Lightweight yet durable designs enable machinery to operate at higher efficiencies while reducing overall operational costs.

Conclusion

Single hydraulic cylinder manufacturers are critical players in the industrial ecosystem, driving innovation and quality within hydraulic systems. Their commitment to excellence ensures that industries relying on these components can operate smoothly, efficiently, and safely. As technology advances and more companies seek to optimize their operations, the demand for high-quality hydraulic cylinders will likely continue to rise, solidifying the role of these manufacturers in shaping the future of modern industry. Through their expertise and dedication, they not only supply critical components but also contribute significantly to the advancement of manufacturing practices on a global scale.

-

Exploring Hydraulic Cylinder Manufacturing for RV Slide-Out Precision, Reliability, Custom Solutions

NewsJun.24,2025

-

Top Hydraulic Downfeed Control Cylinder Companies Reliable Factory-Sourced Hydraulic Downfeed Control Cylinder Supplier

NewsJun.10,2025

-

China County Line Hydraulic Cylinder Supplier - High Quality & Durable County Line Hydraulic Cylinder Factory & Company

NewsJun.10,2025

-

High-Quality China Hydraulic Trailer Jack Cylinder Manufacturer Reliable Hydraulic Trailer Jack Cylinder Factory and Company

NewsJun.10,2025

-

Custom China Car Carrier Hydraulic Cylinder Durable & High-Performance

NewsJun.10,2025

-

Northern Tool Hydraulic Power Unit Products High-Efficiency Solutions

NewsJun.10,2025