Dec . 15, 2024 05:13 Back to list

Manufacturers of Welding Hydraulic Cylinders for Various Industrial Applications

The Importance of Welding in Hydraulic Cylinder Manufacturing

Hydraulic cylinders are essential components in various industries, including construction, manufacturing, and automotive sectors. These robust devices convert hydraulic energy into mechanical force, facilitating movement and control in machines. The manufacturing of hydraulic cylinders involves several critical processes, with welding playing a pivotal role in ensuring the structural integrity and performance of the final product. This article explores the significance of welding in hydraulic cylinder factories, including its methods, benefits, and best practices.

Understanding Welding in Hydraulic Cylinder Production

Welding is the process of joining two or more pieces of metal together by melting them and allowing them to cool, forming a strong bond. In the context of hydraulic cylinders, welding is primarily used to assemble the cylinder barrel, end caps, and any internal components that must withstand high pressures and loads.

There are several welding methods commonly employed in hydraulic cylinder factories, including

1. MIG (Metal Inert Gas) Welding This technique is popular due to its speed and versatility. It uses a continuous wire feed and an inert gas shield to protect the molten weld from contamination. MIG welding is ideal for thin-walled components, which are typical in hydraulic cylinder construction.

2. TIG (Tungsten Inert Gas) Welding Known for its precision and control, TIG welding is often used for more complex components that require a clean and narrow weld bead. This method employs a non-consumable tungsten electrode and an inert gas to produce high-quality welds, making it suitable for critical hydraulic applications.

3. Submerged Arc Welding This method is employed in situations where deep weld penetration is necessary. The arc is submerged under a blanket of granular fusible flux, which protects the weld area and improves its quality. This technique is often used for large-diameter cylinders, where strength is paramount.

Benefits of Quality Welding in Hydraulic Cylinders

The quality of welds in hydraulic cylinders directly impacts the performance and reliability of the equipment. High-quality welding ensures that the cylinders can withstand extreme pressure, reducing the risk of failure and extending the lifespan of the product. Key benefits of quality welding include

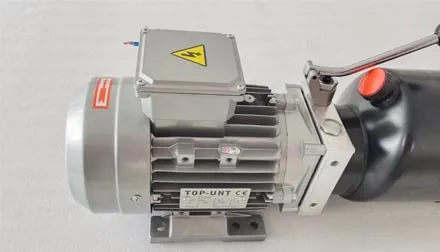

welding hydraulic cylinder factories

- Enhanced Strength Properly welded joints are often stronger than the base materials themselves, providing the necessary durability for heavy-duty applications. - Pressure Resistance Quality welds can handle the high pressure exerted by hydraulic fluids, preventing leaks and failures that could result in costly downtimes and repairs. - Improved Safety Well-welded hydraulic cylinders minimize risks associated with equipment malfunction, contributing to safer working environments.

Best Practices for Welding in Hydraulic Cylinder Factories

To achieve optimal results in welding hydraulic cylinders, manufacturers should follow best practices that ensure efficiency and product quality

1. Employee Training Skilled welders are crucial to the success of hydraulic cylinder production. Ongoing training and certification programs help ensure that workers are proficient in the latest welding techniques and safety protocols.

2. Quality Materials Using high-quality materials and consumables is essential for producing durable and reliable hydraulic cylinders. Factories must source materials that meet industry standards and specifications.

3. Regular Inspections Implementing a rigorous inspection process for weld quality is key to identifying defects early and preventing potential failures. Non-destructive testing methods, such as ultrasonic or radiographic inspections, can help detect issues without compromising the integrity of the components.

4. Adherence to Standards Compliance with industry standards, such as ASTM and ISO, ensures that hydraulic cylinders are manufactured to meet safety and performance benchmarks.

5. Continual Improvement Manufacturers should regularly evaluate their processes and seek ways to enhance efficiency, reduce waste, and improve weld quality.

Conclusion

Welding is a fundamental aspect of hydraulic cylinder manufacturing that significantly affects the performance and safety of industrial equipment. Through employing advanced welding techniques, adhering to best practices, and ensuring high-quality control, hydraulic cylinder factories can produce reliable and durable products that meet the demands of various industries. Investing in welding technology and training will not only enhance product performance but also position manufacturers for success in a competitive marketplace.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025