Dec . 07, 2024 09:15 Back to list

tow truck hydraulic cylinder factory

Understanding Tow Truck Hydraulic Cylinder Factories

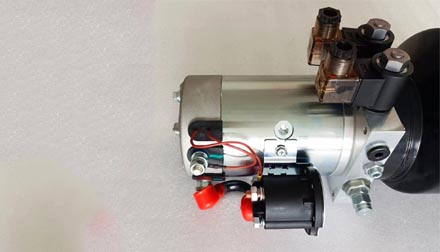

Tow trucks are essential vehicles in the realm of roadside assistance, capable of rescuing stranded vehicles and facilitating their transport. A critical component of these tow trucks is the hydraulic cylinder, responsible for the lifting and lowering mechanisms that enable safe and efficient towing. The production of hydraulic cylinders specifically tailored for tow trucks takes place in specialized factories dedicated to engineering, manufacturing, and quality control processes. This article delves into the intricacies of tow truck hydraulic cylinder factories, illustrating their importance in the automotive industry.

The Role of Hydraulic Cylinders in Tow Trucks

Hydraulic cylinders are vital to the functionality of tow trucks. These devices utilize the principles of hydraulics—specifically, the incompressibility of fluids—to generate significant force with minimal effort. In tow trucks, hydraulic cylinders facilitate lifting the vehicle being towed or repositioning the tow bed. When operators engage the hydraulic system, fluid is forced into the cylinder, extending a piston that ultimately lifts the tow bed or the vehicle on it. The efficiency and reliability of this system are paramount, as they directly impact safety and effectiveness during roadside operations.

The Manufacturing Process

Tow truck hydraulic cylinder factories engage in a multi-step process to manufacture these critical components. The process generally begins with the selection of high-quality raw materials, typically alloy steels or other durable metals. The chosen materials must withstand high pressure and harsh operating conditions, ensuring longevity and resilience.

Once the materials are selected, they undergo several manufacturing stages, including

1. Cutting and Shaping Raw materials are cut into appropriate lengths and shaped using advanced CNC (computer numerical control) machinery to achieve precise specifications.

2. Welding Components like the cylinder body and end caps are welded together to form a robust unit. This step is crucial, as strong welds contribute to the integrity of the hydraulic cylinder.

tow truck hydraulic cylinder factory

3. Machining The welded parts are then machined to create smooth surfaces and ensure accurate fitting of the internal components. Precision in this stage is vital, as any irregularities can lead to leaks or mechanical failures.

4. Assembly The hydraulic cylinders are assembled with seals, pistons, and other internal components. Each part must be carefully selected and fitted to maintain the cylinder's operational efficiency.

5. Testing Finally, the assembled cylinders undergo rigorous testing to ensure they can withstand specified pressure levels. This quality control measure is essential for guaranteeing that the cylinders meet or exceed industry standards.

Innovations and Technologies in Hydraulic Cylinder Production

Tow truck hydraulic cylinder factories are at the forefront of innovation within the hydraulic systems industry. As technology advances, so do the manufacturing processes and the materials used. Factories are increasingly adopting automation and robotics, which enhance production efficiency and consistency. Additionally, advancements in material science are leading to the development of lighter yet stronger alloys, improving overall performance.

Furthermore, the demand for eco-friendly manufacturing processes has led many factories to explore sustainable practices. This includes recycling scrap materials and reducing waste generated during production. The focus on sustainability not only benefits the environment but also appeals to the growing number of consumers prioritizing eco-conscious products.

Conclusion

In summary, the role of tow truck hydraulic cylinder factories is indispensable to the automotive industry. Their meticulous manufacturing processes and commitment to quality ensure that tow trucks are equipped with reliable hydraulic systems, enhancing roadside assistance operations. As factories continue to innovate and adapt to technological advancements, they will play a critical role in shaping the future of towing and recovery services. Without these dedicated facilities, the efficiency and safety of towing operations would be significantly compromised, underscoring the importance of hydraulic cylinder production in today's automotive landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025