Aug . 01, 2024 01:37 Back to list

Top Quality Hydraulic Cylinder Manufacturers for Automotive Applications and Performance Solutions

The Evolution and Importance of Car Hydraulic Cylinder Manufacturers

In the automotive industry, hydraulic systems play a critical role in ensuring the efficient operation of vehicles. Among the essential components of these systems are hydraulic cylinders, which are vital for various applications including steering, braking, and suspension. Car hydraulic cylinder manufacturers have become pivotal players in the automotive supply chain, as they supply the necessary components that enhance vehicle performance, safety, and reliability.

Hydraulic cylinders operate by converting hydraulic energy into mechanical force. When hydraulic fluid is pumped into the cylinder, it generates pressure that pushes a piston inside the cylinder, resulting in the movement of vehicle components. This principle is instrumental in numerous automotive applications, including power steering systems, automatic transmissions, and active suspension systems. The functionality of these systems is heavily reliant on the quality and reliability of the hydraulic cylinders produced by manufacturers.

The evolution of car hydraulic cylinder manufacturing can be traced back to the early 20th century when hydraulic systems began to gain traction in industrial applications. As the automotive industry rapidly expanded in the post-World War II era, the demand for hydraulic components soared. Manufacturers adapted to this need by developing advanced production techniques and innovative designs that improved the performance and lifespan of hydraulic cylinders.

Today, car hydraulic cylinder manufacturers utilize state-of-the-art technologies to enhance their production processes. Modern manufacturing techniques such as computer numerical control (CNC) machining, laser cutting, and precision welding have revolutionized the industry. These technologies allow for increased accuracy, reducing the margin for error and ensuring that the hydraulic cylinders produced meet the stringent standards required by automakers.

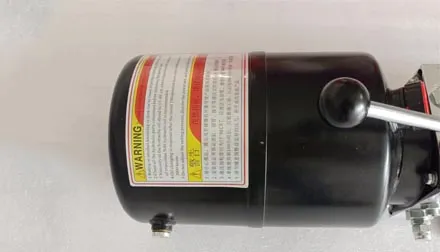

car hydraulic cylinder manufacturer

Quality control is another crucial aspect of hydraulic cylinder manufacturing. Leading manufacturers implement rigorous testing protocols to ensure that their products can withstand the harsh conditions of automotive applications. This includes pressure testing, fatigue testing, and thermal testing. By adhering to high-quality standards, manufacturers can guarantee that their cylinders provide the necessary performance while minimizing the risk of failure.

Moreover, the rise of electric and hybrid vehicles is reshaping the landscape for hydraulic cylinder manufacturers. These vehicles often employ advanced hydraulic systems for various functionalities, such as regenerative braking and adaptive steering. As the industry shifts towards more sustainable solutions, manufacturers must innovate continuously to meet the changing demands of automakers. This includes developing lighter, more efficient cylinders that can operate under different environmental conditions.

The importance of car hydraulic cylinder manufacturers extends beyond simply producing components. They play a vital role in the overall safety and efficiency of vehicles. A well-functioning hydraulic system ensures that critical systems, such as brakes and steering, operate smoothly, preventing accidents and enhancing the driving experience. As such, the relationship between automotive manufacturers and hydraulic cylinder producers is one of collaboration and mutual reliance.

Furthermore, with increasing globalization, manufacturers are expanding their reach beyond domestic markets. Many hydraulic cylinder manufacturers have established partnerships with international automotive companies, leading to a wider distribution network and increased investment in research and development. This globalization fosters innovation and encourages the sharing of best practices, ultimately benefiting consumers with better-quality vehicles.

In conclusion, car hydraulic cylinder manufacturers are key contributors to the automotive industry. Their role in producing high-quality, reliable hydraulic components is essential for the safety and performance of modern vehicles. Through continuous innovation, strict quality control, and a commitment to meeting evolving industry demands, these manufacturers will remain integral to the development of automotive technology in the years to come. As vehicles become more advanced and environmentally friendly, the expertise and contributions of hydraulic cylinder manufacturers will be more critical than ever.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025