Dec . 15, 2024 03:32 Back to list

Small Hydraulic Cylinder Manufacturing Company Focused on Quality and Innovation

The Tiny Hydraulic Cylinder Factory Precision Engineering at Its Best

In the realm of industrial machinery, the significance of hydraulic systems cannot be overstated. Among the various components that make up these intricate systems, hydraulic cylinders play a pivotal role. Tiny hydraulic cylinder factories, specializing in the production of these compact yet powerful components, demonstrate the perfect blend of advanced engineering, innovation, and dedication to quality.

The Importance of Hydraulic Cylinders

Hydraulic cylinders are devices used to convert hydraulic energy into mechanical force. They operate on the principles of fluid mechanics and are designed to produce linear motion and force. In a variety of applications, from construction equipment to aerospace technology, these cylinders provide the necessary power to perform tasks ranging from lifting heavy loads to precise movements in robotic systems.

The appeal of tiny hydraulic cylinders lies in their versatility and compact design. These miniaturized cylinders are essential in applications where space is limited, yet strong performance is required. Industries such as automotive manufacturing, medical device production, and robotics benefit from the efficiency of these small but mighty components.

Craftsmanship and Technology

At a tiny hydraulic cylinder factory, precision is paramount. The design and manufacturing process involves a combination of traditional craftsmanship and cutting-edge technology. Engineers start by designing cylinders that meet specific performance requirements, including stroke length, bore size, and pressure ratings. Computer-aided design (CAD) software enables these engineers to create detailed blueprints that guide the production process.

Once designed, the manufacturing stage begins. Factories employ advanced machining techniques such as CNC (Computer Numerical Control) machining, which allows for high precision in manufacturing components. This process ensures that each cylinder is produced to exact tolerances, meeting the stringent quality standards required in various industries.

In addition to CNC machining, the assembly process is critical. Each tiny hydraulic cylinder comprises multiple parts, including the cylinder barrel, piston, seals, and end caps. Skilled technicians meticulously assemble these components, ensuring that they fit perfectly to prevent leaks and ensure optimal performance. Quality control measures, including pressure testing and dimensional checks, are implemented throughout the assembly process to maintain high standards.

Materials and Durability

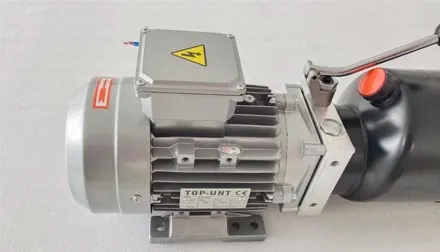

tiny hydraulic cylinder factory

Choosing the right materials is crucial in the production of tiny hydraulic cylinders. Typically, high-strength alloys or stainless steel are used to withstand high pressure and extend the product's lifespan. The selected materials must also be resistant to corrosion, especially in applications involving exposure to harsh environments.

Furthermore, advancements in material science have led to the development of composite materials that offer superior strength-to-weight ratios. This technology allows for the production of lighter cylinders without compromising performance, making them ideal for applications in aerospace and robotics, where weight considerations are critical.

Customization and Customer Service

One of the defining features of many tiny hydraulic cylinder factories is their ability to provide customized solutions to meet specific customer needs. By working closely with clients, manufacturers can modify existing designs or create entirely new products tailored to unique specifications. This flexibility enhances the factory's reputation and ensures customer satisfaction.

Additionally, excellent customer service is a hallmark of successful hydraulic cylinder factories. Manufacturers understand the importance of timely delivery and responsive communication, especially for customers in fast-paced industries. Establishing long-term relationships with clients through reliability and support is vital for sustained business success.

Environmental Considerations

In today’s climate-conscious world, many tiny hydraulic cylinder factories are integrating sustainable practices into their manufacturing processes. This includes reducing waste, recycling materials, and optimizing energy consumption. By prioritizing environmentally friendly practices, these factories not only contribute to a greener planet but also appeal to a growing demographic of eco-conscious consumers.

Conclusion

Tiny hydraulic cylinder factories stand at the forefront of engineering innovation, playing a crucial role in a diverse range of industries. Through precision manufacturing, a commitment to quality, and a focus on customization, these factories produce components that are essential for the efficiency and effectiveness of hydraulic systems worldwide. As technology and materials continue to evolve, the future of tiny hydraulic cylinders looks promising, with endless possibilities for new applications and advancements in performance. Whether for lifting heavy machinery or enabling delicate movements in robotics, tiny hydraulic cylinders are vital components in the machinery that drives our modern world.

-

Premium Car Tailgate Power Units Reliable OEM Solutions

NewsMay.31,2025

-

China's Premium Hydraulic Cylinders Superior Power & ISO-Certified Force

NewsMay.31,2025

-

Boarding Axle Power Units Trusted Manufacturer & Supplier

NewsMay.30,2025

-

Custom Automotive Lift Power Units High-Performance & Durable Solutions

NewsMay.30,2025

-

China Balanced Hydraulic Cylinder Manufacturer High-Performance & Durable Solutions

NewsMay.30,2025

-

Wrecker Hydraulic Cylinders Heavy-Duty & Custom Solutions

NewsMay.29,2025