Nov . 12, 2024 06:20 Back to list

through hole hydraulic cylinder factory

The Through Hole Hydraulic Cylinder Factory A Comprehensive Overview

Hydraulic cylinders are essential components in a wide range of machinery and equipment, providing the force needed to perform tasks such as lifting, pushing, pulling, and moving heavy objects. Among the different types of hydraulic cylinders, through hole hydraulic cylinders stand out due to their unique design and versatility. This article provides an in-depth look at through hole hydraulic cylinders and the significance of their manufacturing in a dedicated factory.

What is a Through Hole Hydraulic Cylinder?

A through hole hydraulic cylinder, also known as a telescopic hydraulic cylinder, is characterized by having a central hole that runs through its entire length. This feature allows for the passage of other components such as rods or pipes through the cylinder itself, enabling it to perform various functions without the need for additional connections. These types of cylinders are commonly used in applications where space is limited, and a compact design is critical.

The basic structure of a through hole hydraulic cylinder includes a cylinder barrel, piston, and end caps. The hydraulic fluid enters through the inlet port, creating pressure that moves the piston and generates mechanical force. The through hole design not only minimizes the required space but also optimizes the force transmission efficiency, making it ideal for applications in construction, manufacturing, and automotive industries.

The Manufacturing Process

The production of through hole hydraulic cylinders involves several key stages, each requiring precision engineering and state-of-the-art technology.

1. Materials Selection The first step in manufacturing involves selecting high-quality materials that can withstand high pressures and extreme conditions. Common materials include high-strength steel and aluminum alloys, which provide the necessary durability while keeping the cylinder lightweight.

2. Machining The cylinder components are machined to precise dimensions using advanced CNC (Computer Numerical Control) machines. This process ensures that each part meets the strict tolerances required for optimal performance and reliability.

3. Welding and Assembly After machining, the parts are carefully welded and assembled. This step is critical for ensuring the structural integrity of the hydraulic cylinder, as any defects in the welds could lead to failure under pressure.

through hole hydraulic cylinder factory

4. Surface Treatment To enhance durability and resistance to wear, surface treatment processes such as hard anodizing or chrome plating are applied. These treatments protect the cylinder from corrosion and reduce friction, contributing to a longer service life.

5. Testing Quality control is vital in the manufacturing process. Each hydraulic cylinder undergoes rigorous testing to ensure it meets performance and safety standards. Tests may include pressure testing, leak testing, and performance evaluations under various loads.

Applications of Through Hole Hydraulic Cylinders

Through hole hydraulic cylinders are used across a wide range of industries, demonstrating their versatility and reliability. Some common applications include

- Construction Equipment In excavators and cranes, these cylinders provide the necessary force to lift and maneuver heavy loads, making them indispensable in construction sites.

- Agricultural Machinery In tractors and harvesters, through hole hydraulic cylinders help in various tasks such as lifting attachments and adjusting equipment height.

- Automotive Industry These cylinders are also utilized in automotive applications, particularly in hydraulic lifts and jacks, where space-saving designs are crucial.

- Manufacturing Processes Many manufacturing machines, such as presses and conveyors, integrate through hole hydraulic cylinders to increase efficiency and performance.

Conclusion

The through hole hydraulic cylinder factory plays a pivotal role in the modern manufacturing landscape. By providing high-quality, durable, and reliable hydraulic cylinders, these factories support various industries that rely on hydraulic power for their operations. As technology advances, the design and manufacturing processes of these cylinders will continue to evolve, leading to even more innovative applications and improved performance. The future of through hole hydraulic cylinders looks promising, with growing demand and ever-increasing applications paving the way for further advancements in this essential technology.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

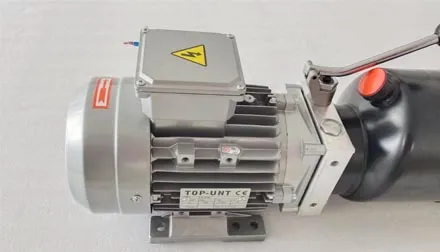

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025