Nov . 11, 2024 10:46 Back to list

tailplate hydraulic cylinder

Understanding Tailplate Hydraulic Cylinders Design, Function, and Applications

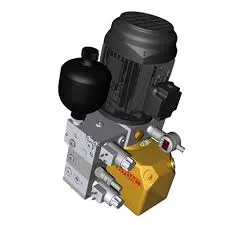

Hydraulic cylinders are integral components in various machinery and equipment, providing the necessary force and movement to facilitate operations in industries ranging from construction to manufacturing. Among the different types of hydraulic cylinders, tailplate hydraulic cylinders play a crucial role, especially in applications involving heavy lifting and precise positioning. This article delves into the design, function, and applications of tailplate hydraulic cylinders, highlighting their importance in modern industrial processes.

Design Features

A tailplate hydraulic cylinder typically consists of a cylindrical barrel, a piston, and a tailplate. The barrel houses the hydraulic fluid, while the piston moves within it to generate linear motion. The tailplate, an essential part of the cylinder, is attached to the piston rod and serves as the point of connection to the machinery or load being moved. The design of tailplate hydraulic cylinders is often guided by the specific requirements of the application, including the load capacity, stroke length, and pressure ratings.

These cylinders are engineered to withstand high pressures and dynamic loads, making them suitable for demanding environments. Manufacturers utilize durable materials such as high-strength steel or aluminum alloys to ensure longevity and reliability. Additionally, tailored seals and coatings are employed to minimize leakage and reduce wear and tear, significantly extending the lifespan of the equipment.

Operational Mechanism

The operation of a tailplate hydraulic cylinder is relatively straightforward. When hydraulic fluid is pumped into the cylinder, it creates pressure, forcing the piston to move. This movement translates into mechanical force that can lift, push, or pull loads as required. The tailplate enables smooth connection to attachments or equipment, enhancing the functional capacity of the cylinder.

tailplate hydraulic cylinder

One of the notable advantages of using hydraulic cylinders, including tailplate variants, is their ability to provide a continuous and controllable flow of power. Operators can precisely control the speed and force exerted by the cylinder, allowing for meticulous positioning and handling of heavy objects. This makes tailplate hydraulic cylinders ideal for applications that require both strength and precision.

Applications

Tailplate hydraulic cylinders find utility in various sectors, including construction, manufacturing, automotive, and more. In the construction industry, these cylinders are often used in heavy machinery such as excavators and backhoes, enabling operators to perform tasks such as digging, lifting, and demolition efficiently. The robustness of tailplate cylinders makes them perfect for handling substantial loads, thereby enhancing productivity on construction sites.

In manufacturing, tailplate hydraulic cylinders are employed in assembly lines and automation processes where precise movements are crucial. Conveyor systems, for instance, may utilize these cylinders to ensure smooth movement of goods and materials between different phases of production. The ability to operate under high pressure while maintaining accuracy makes tailplate hydraulic cylinders indispensable in this context.

Moreover, the automotive industry uses these cylinders in various applications, from lifting car frames during assembly to powering various mechanisms in vehicle manufacturing. Their adaptability to different conditions and requirements ensures that tailplate hydraulic cylinders remain a cornerstone in the efficiency of automotive production lines.

Conclusion

In summary, tailplate hydraulic cylinders are vital components in a range of industrial applications. Their robust design, efficient operational mechanics, and versatility make them indispensable in environments where heavy lifting and precision are required. As industries continue to advance and evolve, the role of tailplate hydraulic cylinders will likely expand, driven by the demand for more efficient and powerful machinery. Understanding the significance of these hydraulic systems not only underscores their importance in current industrial practices but also hints at a future where innovations in hydraulic technology may further optimize their performance and versatility.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025