Aug . 11, 2024 05:32 Back to list

Steps to Rebuild a Hydraulic Cylinder for Enhanced Performance and Longevity in Manufacturing

Rebuilding a Hydraulic Cylinder A Guide for Manufacturers

Hydraulic cylinders are essential components in numerous industrial applications, providing the force needed to lift, push, or move heavy loads. Over time, these cylinders may wear out or become damaged, leading to decreased efficiency and potential operational failures. For manufacturers, understanding the process of rebuilding hydraulic cylinders is crucial for maintaining equipment and ensuring optimal performance.

Understanding Hydraulic Cylinder Maintenance

Before diving into the rebuilding process, it's important to understand the common issues that can arise in hydraulic cylinders. These problems often include seal wear, rod damage, and cylinder bore degradation. Regular maintenance and inspections can help identify these issues early, allowing for timely repairs that can prolong the life of the hydraulic cylinder. However, when repairs are not enough, rebuilding may be necessary.

The Rebuilding Process Step-by-Step

1. Disassembly The first step in rebuilding a hydraulic cylinder is to disassemble it carefully. This involves removing the cylinder from the machine, disconnecting the hydraulic lines, and taking apart the end caps, rod, and piston. Use care during this process to avoid damaging any components that may be reusable.

2. Inspection Once disassembled, every part of the hydraulic cylinder should be thoroughly inspected for wear and damage. Look for scoring or scratches on the cylinder bore, pitting on the piston, and any signs of deterioration in seals or O-rings. It is advisable to use calipers and micrometers to measure dimensions accurately.

3. Cleaning Clean all components using appropriate cleaning solutions to remove any dirt, debris, or hydraulic fluid. Ensure that there are no foreign particles left, as these can lead to premature failure once the cylinder is reassembled.

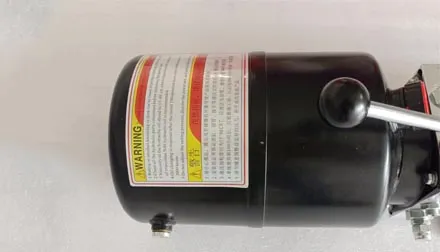

rebuild a hydraulic cylinder manufacturer

4. Replacement of Worn Parts After inspection and cleaning, replace any components that are found to be worn or damaged. This often includes seals, O-rings, and sometimes even the piston or rod if they are severely corroded or scratched. When sourcing replacement parts, ensure they meet OEM specifications to guarantee compatibility and performance.

5. Reassembly With all cleaned and replaced components, the next step is to reassemble the hydraulic cylinder. Follow the manufacturer’s specifications for torque settings and assembly sequences. Proper alignment is key to preventing future leaks and ensuring smooth operation.

6. Testing After reassembly, it’s crucial to conduct performance tests to ensure the hydraulic cylinder is functioning correctly. This includes pressure testing to check for leaks and operational testing to assess performance under load conditions. Any issues identified during testing must be rectified before the cylinder is returned to service.

Benefits of Rebuilding Over Replacing

Rebuilding hydraulic cylinders can offer several advantages compared to replacing them outright. First and foremost, it is often a more cost-effective solution, allowing manufacturers to save money while extending the life of their equipment. Rebuilding also promotes sustainability by reducing the number of discarded components, contributing to environmental conservation efforts.

Moreover, through the rebuilding process, manufacturers can enhance the performance of hydraulic systems. By replacing worn parts and addressing existing issues, rebuilt cylinders can operate more efficiently and reliably than their previously fatigued counterparts.

Conclusion

Rebuilding hydraulic cylinders is a vital skill for manufacturers looking to maintain the integrity and performance of their machinery. By understanding the rebuilding process—from disassembly and inspection to cleaning and replacement—manufacturers can ensure their hydraulic systems remain in optimal working condition. Not only does this practice support operational efficiency, but it also fosters sustainability within industrial practices, making it a win-win situation for both manufacturers and the environment.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025