Nov . 08, 2024 20:08 Back to list

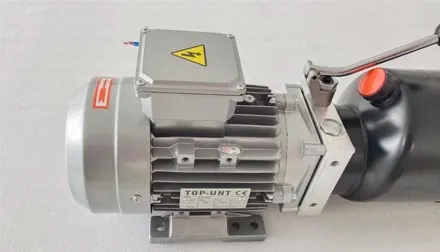

stacker car power unit product

The Advancements in Stacker Car Power Units

In the realm of industrial automation and logistics, stacker cars have emerged as a vital component for enhancing operational efficiency. The power unit that drives these stacker cars plays a critical role in their performance, reliability, and overall effectiveness. As industries evolve, so do the power units powering these indispensable machines.

Understanding Stacker Cars

Stacker cars are automated vehicles designed to transport materials within warehouses and manufacturing facilities. Their primary function is to handle heavy loads efficiently, thereby optimizing space and reducing manual labor. These vehicles can operate autonomously or under human supervision, depending on the sophistication of the system in place. With the rise of e-commerce and just-in-time manufacturing, the demand for stacker cars has surged, prompting innovations in their power units.

The Importance of Power Units

At the heart of every stacker car lies its power unit, which typically utilizes electric battery technology. These power units are responsible for supplying the necessary energy to operate the vehicle's movement, lifting mechanisms, and other functions. A reliable power unit significantly impacts the stacker car's operational efficiency, uptime, and maintenance costs. Therefore, investing in advanced power unit technologies is crucial for companies looking to enhance their material handling capabilities.

Innovations in Power Unit Technology

Recent advancements in power unit technology have revolutionized the performance of stacker cars. Among the most notable developments is the shift from traditional lead-acid batteries to more efficient lithium-ion batteries. Lithium-ion batteries are lighter, longer-lasting, and capable of faster charging compared to their lead-acid counterparts. They offer a higher energy density, allowing stacker cars to operate for extended periods without the need for frequent recharging.

stacker car power unit product

Additionally, modern power units are incorporating smart technology, enabling real-time monitoring of battery health and performance. This feature allows operators to predict battery life and schedule maintenance, thereby minimizing downtime. Moreover, automated charging stations equipped with advanced sensors can optimize charging cycles, ensuring that stacker cars are always ready for operation.

Environmental Considerations

As sustainability becomes a priority for many organizations, the development of environmentally friendly power units is also gaining traction. Manufacturers are investing in greener technologies and materials to reduce the carbon footprint of stacker cars. Innovations such as regenerative braking systems can capture and store energy during operation, further enhancing energy efficiency and reducing overall power consumption.

The Future of Stacker Car Power Units

Looking ahead, the future of stacker car power units appears promising. Research into hydrogen fuel cells is underway, with the potential to power stacker cars with clean energy. This technology could offer even more extended operational periods and faster refueling options compared to conventional batteries. Additionally, advancements in artificial intelligence and automation will likely lead to even smarter power units that can self-regulate energy usage based on the vehicle's operational patterns.

Conclusion

In conclusion, the stacker car power unit represents a critical component of modern industrial operations. With ongoing advancements in battery technology, smart systems, and sustainability initiatives, the future of stacker cars is bright. As companies strive for efficiency and reduced operational costs, investments in innovative power units will be essential. By embracing these developments, organizations can not only enhance their material handling capabilities but also contribute to a more sustainable industrial landscape. As the logistics industry continues to evolve, stacker cars and their power units will remain at the forefront of this transformation, driving efficiency and innovation.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025