Oct . 10, 2024 06:11 Back to list

small electric hydraulic cylinder factory

The Small Electric Hydraulic Cylinder Factory A Revolution in Precision Engineering

In recent years, the demand for advanced automation and precision engineering in various industries has surged. This trend has fueled the emergence of highly specialized factories, such as the small electric hydraulic cylinder factory. These facilities play a critical role in manufacturing hydraulic cylinders that combine the efficiency of traditional hydraulic systems with the precision and controllability afforded by electric technologies. This article explores the significance, operations, and innovations of small electric hydraulic cylinder factories.

Understanding Electric Hydraulic Cylinders

Electric hydraulic cylinders are vital components in many applications, including manufacturing machinery, robotics, and mobile equipment. Unlike traditional hydraulic cylinders that rely on hydraulic fluids and pumps, electric hydraulic cylinders utilize electric motors to drive the hydraulic action. This technology offers several advantages, including enhanced energy efficiency, reduced noise levels, and improved response time.

Small electric hydraulic cylinder factories focus on producing compact, high-performance cylinders that cater to specific industrial needs. These cylinders are often designed to deliver precise force and motion control, making them indispensable in environments where accuracy is paramount.

Operations of a Small Electric Hydraulic Cylinder Factory

The operations within a small electric hydraulic cylinder factory involve various steps, from research and development (R&D) to manufacturing and quality control. Initially, engineers and designers collaborate to create innovative designs that meet the specific requirements of clients. This phase often includes computer-aided design (CAD) modeling, simulations, and prototypes to ensure the product's feasibility and performance.

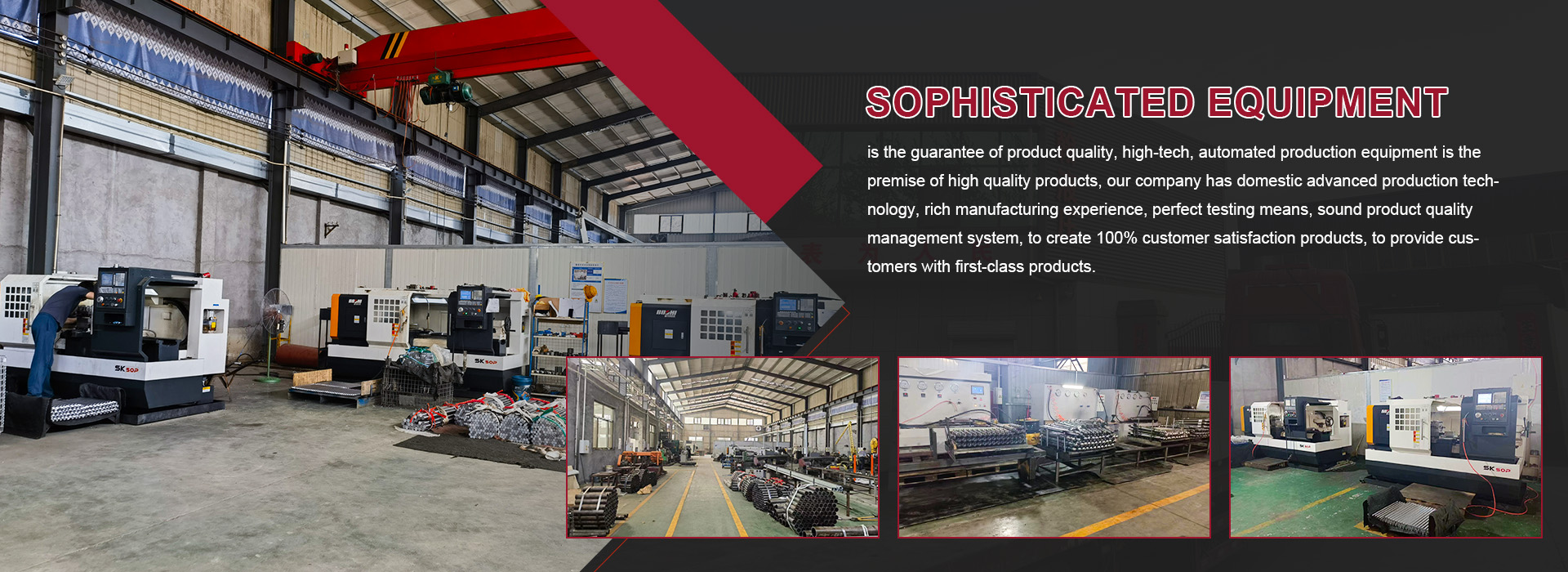

Once the designs are finalized, the manufacturing process begins. A modern small electric hydraulic cylinder factory is equipped with state-of-the-art machinery, including CNC (computer numerical control) machines, laser cutters, and assembly lines that optimize efficiency and precision. The use of automation in these processes significantly reduces human error and increases production speed.

small electric hydraulic cylinder factory

Quality control is a critical aspect of the manufacturing process. Each cylinder undergoes rigorous testing to ensure that it meets industry standards and client specifications. Tests may include pressure tests, leak tests, and performance evaluations. Factories often employ specialized software solutions to monitor production processes in real-time, ensuring consistent quality throughout.

Innovations Shaping the Industry

Innovation is at the heart of small electric hydraulic cylinder factories. The incorporation of smart technology into hydraulic systems is a leading trend. Many factories are now producing cylinders equipped with sensors that provide real-time data related to pressure, temperature, and positional accuracy. This data is invaluable for predictive maintenance, allowing users to identify potential issues before they become costly problems.

Additionally, advancements in materials science have led to the development of lightweight yet durable materials. Factories are increasingly utilizing composites and advanced alloys to enhance the structural integrity of hydraulic cylinders while reducing weight. These innovations contribute to greater energy savings and improved overall performance.

Sustainability is another critical focus for small electric hydraulic cylinder factories. Manufacturers are increasingly adopting eco-friendly practices by reducing waste, recycling materials, and optimizing energy consumption. The integration of electric drives in hydraulic systems not only enhances efficiency but also minimizes the environmental impact associated with traditional hydraulic systems that rely on fossil fuels.

Conclusion

The small electric hydraulic cylinder factory stands at the forefront of engineering innovation. By combining the strengths of electric and hydraulic technologies, these factories are revolutionizing the way industries approach automation and precision control. As demands for efficiency, sustainability, and innovation grow, the role of these specialized manufacturers will become even more significant.

Investing in small electric hydraulic cylinders is a strategic move for businesses seeking to enhance their operational efficiency and maintain a competitive edge in the market. As technology continues to evolve, we can expect these factories to lead the charge in developing cutting-edge solutions that cater to the ever-changing needs of various industries. In this dynamic landscape, small electric hydraulic cylinder factories are not just manufacturers; they are pivotal players in the modern industrial ecosystem.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025