Sep . 28, 2024 16:04 Back to list

Innovative Solutions for Single Stage Hydraulic Cylinder Manufacturing and Applications

Single Stage Hydraulic Cylinder A Company Overview

In the realm of industrial machinery, hydraulic systems play a crucial role in a myriad of applications, from manufacturing to construction. Among the various components of these systems, the single stage hydraulic cylinder is a key player, providing the power necessary to execute a range of tasks. This article delves into the significance of a company specializing in single stage hydraulic cylinders, discussing its operations, innovations, and impact on the industry.

Understanding Single Stage Hydraulic Cylinders

Single stage hydraulic cylinders are designed to convert hydraulic energy into linear motion. They are widely used due to their simplicity and efficiency. The basic construction includes a cylinder barrel, a piston, and hydraulic fluid. When hydraulic fluid is pumped into the cylinder, it pushes the piston, creating a mechanical movement that can be harnessed for a myriad of applications, from lifting heavy loads to precise positioning.

The single stage design, characterized by a single acting piston, makes it particularly suited for applications requiring straightforward and reliable performance. This design typically offers a better weight-to-power ratio compared to multi-stage cylinders, making it the preferred choice in various sectors.

A Commitment to Quality and Innovation

A company that specializes in manufacturing single stage hydraulic cylinders invests heavily in quality control and innovative engineering. By focusing on high-quality materials and advanced manufacturing techniques, such companies ensure their products meet stringent safety and performance standards. This attention to detail not only enhances the durability of the hydraulic cylinders but also boosts their efficiency and effectiveness in diverse applications.

Moreover, research and development are central to continually improving hydraulic cylinder designs. Companies in this field often work closely with industry experts and customers to gather insights on application-specific needs and preferences. This collaborative approach drives innovation, leading to the development of customized solutions tailored to meet unique operational challenges.

Diverse Applications

Single stage hydraulic cylinders are employed in a variety of industries, underscoring their versatility. In construction, they are utilized in excavators, bulldozers, and cranes, providing the necessary force to lift heavy equipment and materials. In manufacturing, these cylinders enhance automation processes by enabling precise movements in assembly lines.

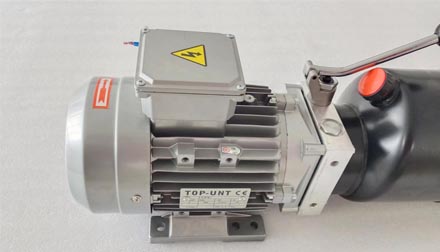

single stage hydraulic cylinder company

Agriculture also benefits from these hydraulic systems, where they are used in tractors and other machinery to facilitate tasks such as plowing, lifting, and transporting. Additionally, even in the realm of material handling, single stage hydraulic cylinders play a critical role in the operation of forklifts and scissor lifts, where reliable lifting mechanisms are essential.

Sustainability and Future Directions

As industries globally shift towards more sustainable practices, hydraulic cylinder companies are also adapting. There is a growing emphasis on energy efficiency, prompting manufacturers to develop cylinders that consume less hydraulic fluid while delivering maximum performance.

Innovative designs that reduce hydraulic leaks—thereby minimizing environmental impact—are becoming increasingly important. The move towards biodegradable hydraulic fluids is also gaining traction, aligning with modern eco-conscious operational strategies. Companies are not only focusing on the performance of their products but also on how environmentally responsible they can be.

The Competitive Edge

The market for single stage hydraulic cylinders is competitive, but quality and reliability give companies a significant edge. Customer service plays an integral role, with manufacturers providing not only products but also support, including installation, maintenance, and troubleshooting.

Moreover, forging strong partnerships with equipment manufacturers and users can lead to mutual benefits. By engaging in collaborative ventures, companies can stay ahead of market trends and better anticipate customer needs, thereby enhancing their product offerings and service capabilities.

Conclusion

The landscape of hydraulic technology continues to evolve, and single stage hydraulic cylinders remain a fundamental component in numerous sectors. Companies committed to innovation, quality, and sustainability are well-positioned to lead in this dynamic industry. As they navigate the challenges and opportunities within the market, their contributions will undoubtedly pave the way for future advancements in hydraulic systems, ensuring that they remain essential tools in the industrial machinery arsenal. Whether it's lifting, pushing, or precision moving, single stage hydraulic cylinders will continue to be vital enablers of progress across various fields.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025