Oct . 09, 2024 05:25 Back to list

single rod hydraulic cylinder factory

Understanding Single Rod Hydraulic Cylinder Manufacturing

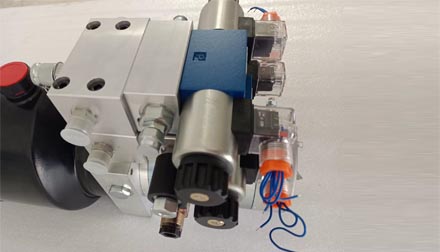

In the realm of engineering and machinery, hydraulic systems play a pivotal role in powering various applications across different industries. Among the key components of these systems is the hydraulic cylinder, particularly the single rod hydraulic cylinder. This article will explore the intricacies of single rod hydraulic cylinder manufacturing, including its design, applications, and the factors influencing production in a factory setting.

The Basics of Hydraulic Cylinders

Hydraulic cylinders are mechanical devices that convert hydraulic energy into linear motion. They consist of a cylinder barrel, a piston, and a rod. The single rod version features one rod extending out from the cylinder, which makes it less complex but equally effective in various applications. The operation relies on the principles of fluid mechanics, where pressurized hydraulic fluid is directed into the cylinder, pushing the piston and performing work.

Design Features

The design of a single rod hydraulic cylinder is critical for its performance and durability. Typically, these cylinders are engineered to withstand high pressures, and they are commonly made from robust materials such as high-strength steel or alloy. The key components include

1. Cylinder Barrel The main body that houses the hydraulic fluid and piston. It must be able to endure the high pressure of the fluid without deforming.

2. Piston This component moves inside the barrel and can be designed in various configurations such as standard, large diameter, or compact.

3. Rod The extension of the piston that transmits force to the external environment. Single rod cylinders feature a rod on one end, allowing for a simpler design compared to double rod cylinders.

4. Seals and Bearings These are crucial for preventing fluid leakage and ensuring smooth operation. High-quality seals can greatly influence the longevity and performance of the cylinder.

The Manufacturing Process

The production of single rod hydraulic cylinders typically involves several key steps

single rod hydraulic cylinder factory

1. Material Selection Manufacturers must select appropriate materials that offer the right balance of strength and weight. Steel grades are often used for their durability and resistance to wear.

2. Machining This involves cutting and shaping the material into precise components. Advanced CNC machining centers are commonly used to achieve the desired tolerances.

3. Assembly Once all components are machined, they are assembled using methods like welding, bolting, or threading. This step requires skilled technicians to ensure that each part fits perfectly to prevent malfunctions.

4. Testing Quality control is paramount in manufacturing. Hydraulic cylinders go through rigorous testing to ensure they can withstand the specified pressures and operate reliably. Common tests include pressure testing, leakage tests, and performance evaluations.

5. Finishing Touches After testing, cylinders may undergo surface treatments, such as painting or coating, to improve resistance to corrosion and enhance longevity.

Applications of Single Rod Hydraulic Cylinders

Single rod hydraulic cylinders are widely used across various industries due to their versatility. Common applications include

- Construction Equipment Used in excavators, loaders, and cranes to provide lifting and digging power.

- Manufacturing Machinery Integral to presses, injection molding machines, and automation systems.

- Transportation Employed in trucks and trailers for hydraulic lifts and suspension systems.

- Agriculture Utilized in tractors and harvesters for various lifting and pulling tasks.

Conclusion

In summary, the manufacturing of single rod hydraulic cylinders involves a meticulous process that ensures these essential components meet rigorous quality and performance standards. Their robust design and versatility make them a fundamental part of hydraulic systems in numerous applications. As industries continue to evolve, the demand for efficient and reliable hydraulic solutions will only intensify, placing importance on the factories that produce these indispensable components. Whether in heavy machinery or complex manufacturing systems, single rod hydraulic cylinders will continue to drive efficiency and performance in the modern industrial landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025