Dec . 03, 2024 16:20 Back to list

Hydraulic Cylinders with Single Action for Efficient Industrial Applications

Understanding Single Action Hydraulic Cylinders An Overview

Hydraulic cylinders play a crucial role in various industrial applications, ranging from construction and manufacturing to automotive and aerospace. Among the different types of hydraulic cylinders, single action hydraulic cylinders stand out for their simplicity and effectiveness in specific scenarios. This article aims to provide a comprehensive overview of single action hydraulic cylinders, exploring their design, operation, applications, and advantages.

What is a Single Action Hydraulic Cylinder?

A single action hydraulic cylinder, also known as a single-acting cylinder, is a type of linear actuator that converts hydraulic energy into mechanical force. Unlike double-acting cylinders, which can exert force in both directions, single action cylinders generate force in one direction only. They rely on a spring or an external force to return to their original position after the hydraulic fluid is released.

Design and Operation

The fundamental design of a single action hydraulic cylinder includes a cylinder barrel, piston, end caps, and ports for hydraulic fluid inlet and outlet. The piston is housed within the cylinder and moves when hydraulic fluid is pumped into the chamber. As the fluid enters one side of the piston, it creates pressure that pushes the piston outward, generating linear force.

Once the hydraulic pressure is released, the piston returns to its original position by the force of gravity, a spring, or an external load. The simplicity of the design contributes to the overall efficiency, making single action hydraulic cylinders suitable for various applications.

Applications

Single action hydraulic cylinders are widely used in various industries due to their specific advantages. Here are some common applications

2. Automotive Industry These cylinders are commonly found in automobile maintenance equipment, such as hydraulic jacks and lifts. They provide the necessary force to lift vehicles for maintenance while allowing for easy lowering through gravity.

3. Construction In construction sites, single action hydraulic cylinders are used in machinery like concrete forms and mobile cranes. Their ability to operate efficiently in high-pressure environments makes them essential in heavy-duty tasks.

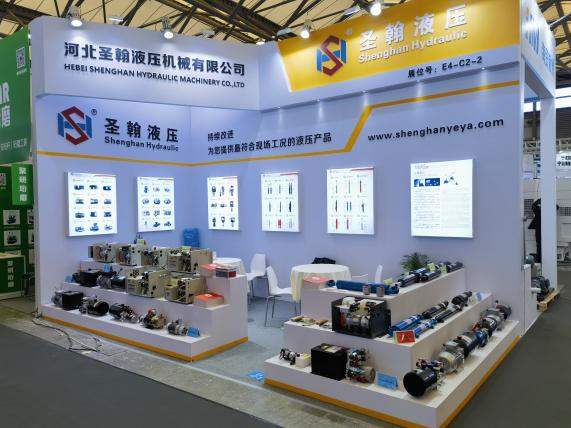

single action hydraulic cylinder products

4. Agriculture They are employed in agricultural machinery, including compactors and balers, where pushing force is required for effective operation.

5. Packaging and Assembly Single action cylinders are utilized in packaging machines for purposes such as pressing, aligning, and shaping products.

Advantages of Single Action Hydraulic Cylinders

Single action hydraulic cylinders offer several benefits that make them a preferred choice for many applications

1. Simplicity Their straightforward design leads to lower manufacturing and maintenance costs. Fewer moving parts mean less wear and tear, making them more durable over time.

2. Less Hydraulic Fluid Usage Since single action cylinders only require fluid during the extension phase, they consume less hydraulic fluid compared to double acting cylinders, leading to cost savings and increased efficiency.

3. Safety The design often includes built-in safety mechanisms, such as springs, which ensure that the piston returns to its original position without requiring additional hydraulic pressure. This feature enhances safety in operations, especially in critical applications.

4. Compact Design Their smaller size and lighter weight make single action hydraulic cylinders easier to integrate into machinery and equipment without compromising space.

5. Reliability Due to their uncomplicated mechanics, these cylinders tend to be more reliable, with a lower risk of failure compared to more complex systems.

Conclusion

In summary, single action hydraulic cylinders are essential components in various industries, providing effective solutions for linear motion tasks. Their simplicity, reliability, and cost-effectiveness make them ideal for applications requiring force in one direction. As technology evolves, the design and functionality of single action hydraulic cylinders continue to improve, ensuring they remain a staple in hydraulic systems around the globe. Understanding their operation and applications can significantly enhance operational efficiency and productivity in industrial settings.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025