Nov . 12, 2024 05:59 Back to list

single acting hydraulic cylinder price manufacturer

Understanding the Cost and Factors Influencing Single Acting Hydraulic Cylinder Prices

In the world of industrial machinery, hydraulic cylinders play a pivotal role in various applications, from construction to manufacturing. Among these, single acting hydraulic cylinders are particularly notable for their simplicity and efficiency. As industries continue to invest in advanced machinery, understanding the price dynamics of single acting hydraulic cylinders and the factors that influence their cost is essential for businesses seeking to make informed purchasing decisions.

What is a Single Acting Hydraulic Cylinder?

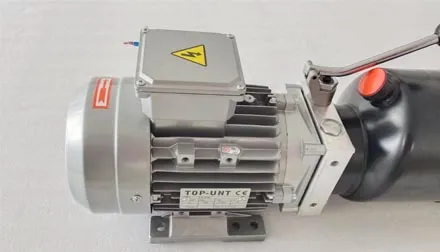

Before diving into pricing, it's important to define what a single acting hydraulic cylinder is. This type of hydraulic cylinder uses fluid pressure to move the piston in one direction, typically providing force during extension. It relies on a spring or another mechanical means to return the piston to its original position. This design is simpler and less expensive than double acting cylinders, making it a popular choice for many applications, including material handling, log splitting, and various automotive tasks.

Price Range for Single Acting Hydraulic Cylinders

The cost of single acting hydraulic cylinders can vary widely based on several factors. Typically, prices can range from $50 to over $500, depending on the size, design, materials, and manufacturer. Smaller cylinders intended for light-duty applications may be on the lower end of this range, while larger, more durable models designed for heavy industrial use will command higher prices.

Key Factors Influencing Prices

1. Size and Capacity The size of the cylinder directly impacts its price. Larger diameter cylinders capable of lifting heavier loads typically cost more due to the increased amount of material used and the engineering precision required. The stroke length, or how far the cylinder can extend, also plays a part in pricing.

single acting hydraulic cylinder price manufacturer

2. Material and Construction The materials used in constructing a hydraulic cylinder significantly influence its durability and performance. High-quality steel or aluminum can raise costs but offers greater longevity and resistance to wear and tear. Additionally, cylinders with advanced coatings or seals that provide better resistance to corrosion or hydraulic fluid contamination may also be priced higher.

3. Manufacturer Reputation Established manufacturers often have a reputation for quality and reliability, which can affect their pricing. While you might find cheaper alternatives, investing in products from reputable manufacturers may lead to greater satisfaction in performance and longevity, ultimately saving money in the long run.

4. Customization and Features Many manufacturers offer customizable options, including specific mounting styles, connection types, and operating pressures. Custom features can lead to increased costs, especially if they require unique engineering or production processes.

5. Bulk Purchasing For businesses looking to purchase multiple units, many manufacturers provide bulk pricing discounts. This can significantly lower the average cost per unit and is often beneficial for companies with ongoing or large-scale projects.

6. Geographic Location Pricing can also be influenced by the geographic location of both the manufacturer and the buyer. Shipping costs, import taxes, and even regional demand can affect prices significantly. It's often beneficial to source local manufacturers when possible to reduce logistical expenses.

Conclusion

In conclusion, the price of single acting hydraulic cylinders can vary widely based on factors such as size, material, manufacturer reputation, and customization options. As industries continue to evolve and require more efficient machinery, understanding these pricing dynamics can help businesses make informed purchasing decisions. By considering not only the upfront costs but also the long-term value provided by quality and durability, companies can ensure they choose the right hydraulic solutions for their specific needs. Whether upgrading existing equipment or investing in new machinery, taking the time to research and compare options will lead to smarter investments and improved operational efficiency.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025