Nov . 07, 2024 06:41 Back to list

Understanding the Mechanism and Function of Single Acting Hydraulic Cylinders

Understanding Single Acting Hydraulic Cylinders

Single acting hydraulic cylinders are an integral part of hydraulic systems used in various industrial applications. Unlike double acting cylinders, which can exert force in both extension and retraction, single acting cylinders use hydraulic pressure to move in one direction only. This unique mechanism makes them particularly suitable for specific tasks, providing both efficiency and simplicity in design.

How Single Acting Hydraulic Cylinders Work

The basic operation of a single acting hydraulic cylinder is relatively straightforward. It consists of a cylinder barrel, a piston, and a spring. Hydraulic fluid is introduced into one side of the piston, creating pressure that drives the piston out of the cylinder. When the pressure is released, the piston returns to its original position, usually facilitated by a spring or the weight of the load itself.

This design is advantageous in scenarios requiring less complex systems. Since only one port is necessary for hydraulic fluid inlet, the overall footprint of the hydraulic mechanism is reduced, allowing for easier installation and maintenance. Furthermore, fewer components translate to a more cost-effective solution, making single acting cylinders popular in applications like lifting, clamping, and pushing.

Applications of Single Acting Hydraulic Cylinders

Single acting hydraulic cylinders are widely employed in various fields such as construction, manufacturing, and automotive industries. In construction, they are often used in equipment like cranes and excavators for lifting and lowering operations. Their ability to exert force in one direction simplifies control and enhances safety when handling heavy loads.

In manufacturing, these cylinders are commonly found in assembly lines where they perform tasks like clamping materials or pushing components into position. They are especially useful in scenarios requiring a swift return cycle, as the presence of a spring mechanism ensures that the piston returns quickly without the need for hydraulic power.

The automotive industry also utilizes single acting cylinders for applications like car jacks, where quick lifting is required followed by gravity-assisted lowering. Their efficiency in these scenarios can significantly reduce the time spent on lifting operations, making them a staple in garages and workshops.

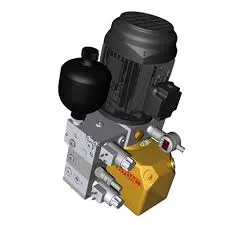

single acting hydraulic cylinder

Advantages of Single Acting Hydraulic Cylinders

The primary advantages of single acting hydraulic cylinders include simplicity, reliability, and cost-effectiveness. Their straightforward design minimizes the chances of malfunctions, making them a dependable choice for many applications. Additionally, the reduced number of hydraulic connections lowers the risk of leaks, further enhancing their reliability.

Another advantage is ease of installation and maintenance. Since these cylinders use only one hydraulic port, they can be installed in compact spaces without the need for complicated piping or control systems. Maintenance requirements are also reduced, as the fewer components mean less wear and tear over time.

Disadvantages of Single Acting Hydraulic Cylinders

Despite their numerous benefits, single acting hydraulic cylinders do face certain limitations. The most significant drawback is that they can only exert force in one direction. This constraint necessitates the use of additional mechanisms for retraction in many applications, which can complicate system design and increase costs.

Furthermore, the reliance on a spring or gravitational force for returning the piston can limit the speed and control of the return stroke, making them less ideal for applications requiring controlled or adjustable retraction.

Conclusion

Single acting hydraulic cylinders are vital components in various hydraulic systems, offering a range of benefits such as simplicity, cost-effectiveness, and reliability. Their specific operational characteristics make them well-suited for certain applications, particularly where lifting and pushing tasks are predominant. While they do have limitations, their advantages often outweigh the drawbacks, ensuring that they remain a popular choice in industries that require dependable hydraulic solutions. Understanding their functionality and applications can help engineers and technicians make informed decisions when designing hydraulic systems tailored to specific operational needs.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025