Dec . 10, 2024 21:18 Back to list

Exploring Hydraulic Cylinder Manufacturing at Simplex Factories for Enhanced Performance and Efficiency

The Importance and Innovations in Simplex Hydraulic Cylinder Factories

In industrial settings, hydraulic cylinders play a pivotal role in powering machinery and equipment. Among the various types of hydraulic cylinders, simplex hydraulic cylinders are particularly significant due to their simplicity in design and efficiency in operation. The factories that manufacture these components have been evolving rapidly, embracing new technologies and methodologies to enhance productivity and quality.

A simplex hydraulic cylinder is a single-acting cylinder that operates on the principle of hydraulic pressure. It uses fluid to create motion in one direction, returning to its original position either through a spring or by the weight of the load. Simplex cylinders are widely used in various applications, including material handling, construction machinery, and automotive industries. Their straightforward design allows for easy maintenance and installation, making them a popular choice for many manufacturers.

Advances in Manufacturing Techniques

Modern simplex hydraulic cylinder factories have adopted advanced manufacturing techniques to enhance efficiency and precision. The use of computer numerically controlled (CNC) machines has revolutionized the production process, allowing factories to produce high-quality cylinders with reduced lead times. CNC technology ensures that each component is manufactured to exact specifications, minimizing errors and waste in the production line.

Additionally, factories are increasingly utilizing automation and robotic processes. Automated systems can undertake repetitive tasks such as welding, painting, and assembly, which not only speeds up production but also reduces the risk of human error. Through these innovations, factories can maintain high levels of quality and consistency across their product range.

Material Selection and Sustainability Practices

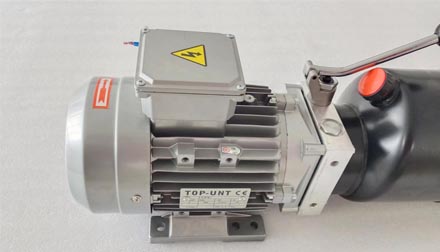

simplex hydraulic cylinder factories

Another important aspect of simplex hydraulic cylinder factories is their approach to material selection. Traditionally, steel has been the primary material used in the manufacturing of hydraulic cylinders due to its strength and durability. However, with the increasing focus on sustainability, many factories are exploring alternative materials that offer comparable performance with a lower environmental impact. For instance, aluminum alloys are gaining popularity for certain applications due to their lightweight properties combined with adequate strength.

Furthermore, many factories are adopting sustainable practices in their operations. This includes recycling metal scraps generated during the manufacturing process and implementing energy-efficient systems to reduce overall energy consumption. By focusing on sustainability, these factories not only contribute to environmental conservation but also appeal to eco-conscious consumers and businesses.

Customization and Market Demand

As industries continue to evolve, the demand for customized hydraulic solutions has surged. Simplex hydraulic cylinder factories are increasingly offering bespoke services to meet specific customer needs. This shift towards customization allows manufacturers to cater to the unique requirements of various applications, whether it’s a specialized size, stroke length, or pressure rating.

Moreover, the global market for hydraulic cylinders is expanding, driven by growth in construction, automotive, and manufacturing sectors. Factories are responding by scaling up production and exploring new markets. This globalization allows for cross-border collaboration and sharing of best practices, further enhancing the quality and reliability of simplex hydraulic cylinders.

Conclusion

Simplex hydraulic cylinder factories are at the forefront of technological innovation in manufacturing. By embracing advanced techniques, sustainable practices, and customization, these factories are well-equipped to meet the dynamic needs of today’s industries. As they continue to evolve, the role of simplex hydraulic cylinders in powering machines will undoubtedly remain significant, driving efficiency and productivity in various sectors. As we look toward the future, it is clear that the innovation and dedication within these factories will play a critical role in shaping the landscape of hydraulic systems globally.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025