Oct . 19, 2024 17:43 Back to list

side link hydraulic cylinder factory

Unveiling the Mechanics of Side Link Hydraulic Cylinders

In the realm of modern manufacturing and heavy machinery, hydraulic cylinders play a pivotal role, especially in applications where force and precision are paramount. Among the various types of hydraulic cylinders, side link hydraulic cylinders have emerged as a key component in enhancing the efficiency of numerous systems, from construction to agriculture. In this article, we delve into the intricacies of side link hydraulic cylinders, their manufacturing processes in factories, and their applications across different industries.

Understanding Side Link Hydraulic Cylinders

Side link hydraulic cylinders are specialized devices designed to convert hydraulic energy into linear motion. They consist of a cylinder, piston, and hydraulic fluid, working in tandem to create force. The side link configuration allows these cylinders to be mounted in a manner that provides better stability and force distribution, making them ideal for applications requiring a high degree of control and precision.

The design of side link hydraulic cylinders is particularly advantageous in scenarios where space is limited, and the force needed to lift or move objects is significant. By efficiently converting hydraulic pressure into linear motion, these cylinders can perform tasks with remarkable accuracy and power. They can be engineered for various stroke lengths and force outputs, tailored to meet the specific needs of different applications.

Manufacturing Process

The manufacturing of side link hydraulic cylinders requires a fusion of advanced technology and skilled craftsmanship. A typical factory producing these cylinders will follow several key steps

1. Material Selection High-quality steel or aluminum is chosen for the construction of the cylinder and piston elements. The choice of material directly impacts the durability and performance of the hydraulic cylinder.

2. Machining Advanced CNC (Computer Numerical Control) machines are employed to shape the cylinder and piston components with precision. This step ensures that the dimensions are exact, allowing for smooth movement and effective sealing.

3. Assembly Once all parts are machined, they are assembled in a clean environment to prevent contamination. Attention to detail during assembly is crucial, as any imperfection can lead to leaks or reduced performance.

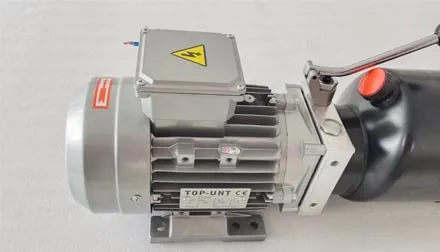

side link hydraulic cylinder factory

4. Testing After assembly, each cylinder undergoes rigorous testing to ensure it meets the required standards for pressure, leakage, and performance. This quality control step is vital to maintain the reliability of the product.

5. Finishing The final touch involves coating or painting the cylinders to protect them from corrosion and wear, especially in harsh environments. This not only enhances durability but also improves the aesthetic appeal of the product.

Applications of Side Link Hydraulic Cylinders

The versatility of side link hydraulic cylinders makes them suitable for a wide range of applications across various industries

- Construction In construction, these cylinders are used in excavators, backhoes, and loaders to provide the necessary lifting and digging force. Their ability to handle significant weights while ensuring stability is invaluable on job sites.

- Agriculture Farmers rely on side link hydraulic cylinders for tractors and other agricultural machinery, where they assist in tasks such as plowing, lifting, and transporting heavy loads. Their efficiency contributes to increased productivity in farming operations.

- Automotive In the automotive sector, these hydraulic cylinders are employed in car lifts, enabling mechanics to safely elevate vehicles for maintenance and repairs.

- Aerospace The precise control offered by side link hydraulic cylinders is essential in aerospace applications, particularly in landing gear mechanisms where reliability is critical.

Conclusion

The evolution of side link hydraulic cylinders reflects the ongoing advancements in hydraulic technology and manufacturing processes. As factories continue to innovate and streamline their production, the potential applications of these cylinders are bound to expand further. With their significant contribution to modern machinery and equipment, side link hydraulic cylinders not only enhance operational efficiency but also drive productivity across diverse industries. The future looks promising, as these sophisticated devices are poised to play an increasingly vital role in the mechanization of various sectors, paving the way for more advanced, efficient, and robust machines.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025