Nov . 12, 2024 08:27 Back to list

screen door hydraulic cylinder factory

The Rise of Hydraulic Cylinders in Screen Door Manufacturing

In the realm of modern manufacturing, the integration of advanced technologies has redefined the production processes across various industries. Among these advancements, hydraulic systems have gained significant traction, especially in the production of screen doors. A screen door hydraulic cylinder factory plays a critical role in this evolution, enabling manufacturers to create efficient, durable, and user-friendly products.

Understanding Hydraulic Cylinders

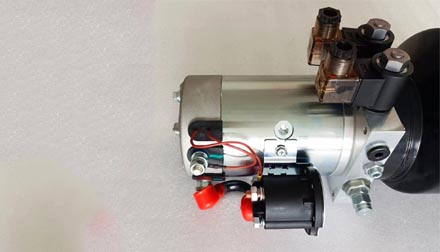

Hydraulic cylinders are essential components in various mechanical systems, converting the energy of hydraulic fluid into linear motion. This mechanism provides immense power, allowing for smooth and controlled movements. In the context of screen doors, hydraulic cylinders are employed to ensure that doors open and close seamlessly, making them easier to handle for users while also prolonging the life of the door and its components.

The Importance of Screen Doors

Screen doors serve various purposes, primarily allowing fresh air to circulate while keeping insects and debris outside. They are commonly used in residential homes, commercial buildings, and even automotive applications. With the increasing demand for eco-friendly and energy-efficient solutions in building design, screen doors have become a staple in modern architecture. This has consequently led to a surge in the need for manufacturing high-quality screen doors equipped with advanced features, including hydraulic mechanisms.

The Role of Factories in Production

A dedicated screen door hydraulic cylinder factory encompasses a full spectrum of operations, from research and development to mass production. These factories are equipped with state-of-the-art machinery and are staffed by skilled professionals specializing in hydraulic systems. They focus on developing hydraulic cylinders specifically designed for screen doors, ensuring that these components meet the required safety and performance standards.

screen door hydraulic cylinder factory

The manufacturing process begins with the meticulous design of hydraulic cylinders, where engineers utilize computer-aided design (CAD) software to simulate and optimize the components for durability and efficiency. Once the designs are finalized, high-quality materials are sourced for production. Often, factories use materials such as steel or aluminum for their strength and resilience in various environmental conditions.

Quality Control and Innovation

Quality control is paramount in any manufacturing process, particularly for components that will be used in structural applications like screen doors. In a hydraulic cylinder factory, rigorous testing protocols are implemented to ensure that each cylinder can withstand pressure and offers consistent performance throughout its lifespan. This includes assessments of tensile strength, pressure resistance, and overall design integrity.

Innovation is also key to staying competitive in the market. Many factories invest in research and development to explore new hydraulic technologies that enhance efficiency and sustainability. This might include the introduction of eco-friendly hydraulic fluids or improved sealing mechanisms that reduce leaks and maintenance needs. Moreover, the trend toward smart home technologies has prompted some factories to integrate sensors and automated controls into their hydraulic systems, allowing for greater precision and user convenience.

The Future of Screen Door Hydraulic Cylinder Manufacturing

As the world increasingly gravitates toward automation and energy efficiency, the future looks promising for screen door hydraulic cylinder factories. Manufacturers are expected to embrace more sustainable practices and incorporate smart technologies into their designs. The continual demand for high-quality, reliable, and user-friendly screen doors guarantees that these factories will play an essential role in shaping the industry landscape.

In conclusion, screen door hydraulic cylinder factories are at the forefront of revolutionizing how we interact with our living spaces. Their advancements not only enhance the functionality of screen doors but also contribute to broader architectural trends focused on sustainability and convenience. As technology continues to evolve, so too will the methods and materials used in these essential manufacturing processes, ensuring a bright future for the industry.

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720-Hebei Shenghan Hydraulic Machinery|Precision Hydraulic Cylinder,Custom Hydraulic Solutions

NewsAug.29,2025

-

1.5 Ton Flipping Oil Cylinder 70/82-40-217-720 | Hebei Shenghan Hydraulic Machinery Co., Ltd.

NewsAug.29,2025

-

High-Precision [90/105-50-180-480] Industrial Component | Durable & Reliable

NewsAug.27,2025

-

High-Performance Set of 50/60-45-290 471 | Durable & Reliable Components

NewsAug.26,2025

-

Efficient Pallet Truck Power Units - Reliable Hydraulic Systems

NewsAug.25,2025

-

Premium Set of 50/60-45-290 471 Parts | High Performance

NewsAug.24,2025