Aug . 28, 2024 03:34 Back to list

High-Quality Reciprocating Hydraulic Cylinder Manufacturers

Exploring the Role of Reciprocating Hydraulic Cylinder Manufacturers

Reciprocating hydraulic cylinders play a vital role in various industries, including construction, manufacturing, and automotive. These devices convert hydraulic energy into mechanical motion, enabling tasks such as lifting, pushing, pulling, and moving heavy loads with precision. As technology advances and industries evolve, the role of manufacturers in the production of these essential components becomes increasingly significant.

A reciprocating hydraulic cylinder operates on the principles of fluid mechanics, utilizing pressurized hydraulic fluid to create force that moves a piston within a cylindrical housing. The efficiency and reliability of these cylinders are crucial for the systems they are integrated into. Thus, the manufacturers of these components are tasked not only with producing high-quality cylinders but also with ensuring consistency, safety, and performance to meet the specific needs of their clients.

Leading manufacturers in the field invest heavily in research and development (R&D) to innovate and improve their product offerings. Modern hydraulic cylinders incorporate advanced materials and engineering techniques that enhance durability and reduce maintenance needs. By focusing on these areas, manufacturers can provide customers with products that offer better performance and longer life cycles, thereby minimizing downtime and repair costs.

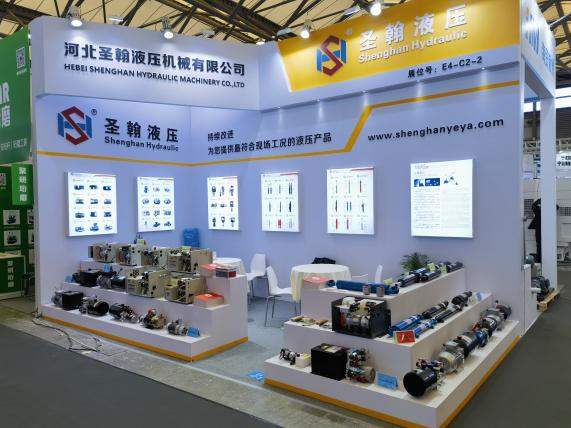

reciprocating hydraulic cylinder manufacturers

Additionally, manufacturers must comply with various industry standards and regulations, ensuring their products meet safety and quality benchmarks. This compliance is crucial, particularly in sectors such as aerospace and automotive, where the failure of a hydraulic cylinder could lead to catastrophic consequences. As a result, manufacturers often work closely with regulatory bodies to stay updated on the latest requirements and certification processes.

Sustainability is another key consideration in the manufacturing of reciprocating hydraulic cylinders. Companies are increasingly adopting eco-friendly practices and materials to reduce their environmental footprint. This shift not only helps in meeting regulatory requirements but also appeals to environmentally conscious consumers. Manufacturers are exploring alternatives like recyclable materials and energy-efficient production processes to contribute to a more sustainable future.

The global market for hydraulic cylinders is competitive, with numerous manufacturers vying for market share. This competition drives innovation and quality improvements. Customers often look for manufacturers that offer customization options, allowing them to tailor products to fit specific applications. The ability to provide bespoke solutions can be a significant differentiator in a crowded marketplace.

In conclusion, the role of reciprocating hydraulic cylinder manufacturers is multifaceted and crucial to the functionality of many industrial systems. From ensuring high-quality production and compliance with safety standards to embracing sustainability, these manufacturers are key players in the advancement of hydraulic technology. As industries continue to evolve, the importance of these manufacturers will only grow, highlighting their integral role in shaping the future of hydraulic systems.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025