Dec . 05, 2024 20:53 Back to list

Guide to Refurbishing a Hydraulic Cylinder for Enhanced Performance and Longevity

Rebuilding a Hydraulic Cylinder A Comprehensive Guide

Hydraulic systems are essential in various industries, from construction to manufacturing, facilitating powerful and precise movements. A critical component within these systems is the hydraulic cylinder, which converts hydraulic energy into linear motion. Over time, hydraulic cylinders may encounter wear and tear, resulting in leaks and reduced efficiency. Fortunately, rebuilding a hydraulic cylinder can restore its function and prolong its lifespan. This article provides a comprehensive guide on how to rebuild a hydraulic cylinder effectively.

Understanding the Hydraulic Cylinder

Before diving into the rebuild process, it's essential to understand the anatomy of a hydraulic cylinder. The primary components include the barrel (or cylinder body), piston, piston rod, seals, and end caps. Each part plays a vital role in the cylinder's operation, so recognizing how they interact is crucial for a successful rebuild.

Tools and Materials Needed

To rebuild a hydraulic cylinder, you will need the following tools and materials

- Hydraulic cylinder repair kit (including seals and O-rings) - Wrenches and sockets - Hydraulic grease - Clean rags or paper towels - A hydraulic press or puller (if necessary) - Measuring calipers or micrometers - A clean workspace

Step-by-Step Rebuilding Process

1. Disassemble the Cylinder Start by draining any remaining hydraulic fluid from the cylinder. Use appropriate containers to collect the fluid for recycling. Then, carefully remove the hydraulic cylinder from the machine. Use wrenches to take off the end caps and carefully pull out the piston rod and piston. Note each component's arrangement for easier reassembly.

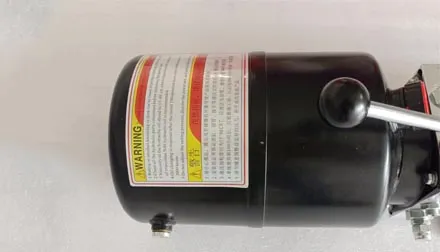

rebuild a hydraulic cylinder product

2. Inspect Components Once disassembled, thoroughly inspect each part for signs of wear or damage. Pay close attention to the piston seals, O-rings, and the barrel's interior surface. Look for scratches, gouges, or pitting, as these can affect performance. Replace any damaged components using your hydraulic repair kit.

3. Clean the Parts Use clean rags and appropriate cleaning solutions to wipe down all cylinder components. Removing old grease, dirt, and fluid residues is crucial for preventing contamination during reassembly. For stubborn residues, a cleaning solution specifically designed for hydraulic systems may be necessary.

4. Replace Seals and O-rings The most common cause of hydraulic cylinder failures is seal failure. Carefully remove old seals and O-rings from the piston and barrel. Replace them with new ones from your repair kit, ensuring they fit correctly. Applying a light coat of hydraulic grease can help the new seals seat properly.

5. Reassemble the Cylinder Begin reassembling the cylinder by inserting the piston back into the barrel. Make sure the seals are seated correctly to prevent leaks. Attach the piston rod and ensure it moves smoothly within the barrel. Replace the end caps and securely tighten them to their specifications.

6. Test for Leaks Before reinstalling the cylinder back into the machine, it's crucial to test it for leaks. Fill it with hydraulic fluid and observe for any signs of leakage around seals and joints. If any leaks are detected, disassemble again to ensure the seals are correctly positioned and intact.

7. Installation and Testing Once the cylinder passes the leak test, it can be reinstalled into the machine. Connect the hydraulic lines and fill the system with the appropriate hydraulic fluid. Operate the machine gently, monitoring the hydraulic cylinder's performance. Ensure it functions smoothly without any abnormal noises or behaviors.

Conclusion

Rebuilding a hydraulic cylinder, while it requires patience and attention to detail, is a manageable task that can save time and money compared to purchasing a new cylinder. By following the steps outlined in this guide, you can restore a hydraulic cylinder to its optimal working condition, ensuring the longevity and efficiency of your hydraulic systems. With proper maintenance and timely repairs, hydraulic cylinders can perform reliably for many years, making them a valuable asset in any industrial operation.

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Precision Hydraulic Solutions

NewsJul.29,2025

-

1.5-Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan Hydraulic Machinery Co., Ltd.|Heavy-Duty Lifting, Precision Engineering

NewsJul.29,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - Hebei Shenghan | Heavy-Duty Hydraulic Solutions

NewsJul.29,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Heavy-Duty Hydraulic Solutions&Precision Engineering

NewsJul.29,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 | Precision Engineering&Industrial Applications

NewsJul.21,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535-Hebei Shenghan|Hydraulic Solution, Industrial Applications

NewsJul.21,2025