Oct . 19, 2024 09:46 Back to list

Top Manufacturers of RC Hydraulic Cylinders for Precision Performance and Durability

The Role of RC Hydraulic Cylinder Manufacturers in Modern Industries

Hydraulic cylinders are essential components in a variety of industrial applications, serving as the backbone for heavy machinery and equipment. Among the types of hydraulic cylinders available in the market, RC (Rod-less or Rod Crown) hydraulic cylinders have gained prominence due to their unique design and operational advantages. This article delves into the significance of RC hydraulic cylinder manufacturers and their impact on various industries.

Understanding RC Hydraulic Cylinders

RC hydraulic cylinders are distinctive in that they do not have an external rod that extends from the cylinder. Instead, the cylinder's design allows for the effective translation of hydraulic pressure into linear motion without the traditional rod. This offers several benefits, including a more compact size, reduced weight, and improved efficiency. The absence of an external rod also eliminates issues related to rod wear and seal damage, which are common in conventional hydraulic cylinders.

Importance of Manufacturers

The role of manufacturers in the hydraulic cylinder industry is critical. They are responsible for the design, engineering, production, and distribution of these vital components. Advanced manufacturing processes, such as precision machining, welding, and assembly, ensure that the hydraulic cylinders meet industry standards and customer specifications. RC hydraulic cylinder manufacturers, in particular, focus on innovation and technological advancements to enhance their products' performance and reliability.

Innovation and Customization

One of the significant contributions of RC hydraulic cylinder manufacturers is their commitment to innovation. In today's competitive market, businesses demand solutions that can optimize operational efficiency and reduce costs. Manufacturers invest in research and development to create customized hydraulic cylinders that cater to specific needs. These customized solutions often lead to improved performance in various applications, such as construction, agriculture, and manufacturing.

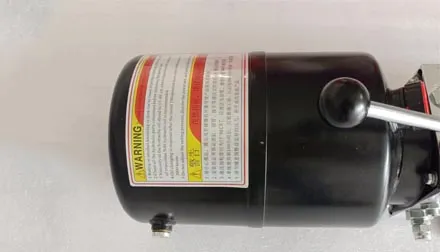

rc hydraulic cylinder manufacturers

For instance, manufacturers can tailor the size, pressure ratings, and materials of RC hydraulic cylinders to suit the requirements of specific machines or environments. This customization allows industries to achieve higher levels of productivity, as equipment can operate more smoothly and with less downtime.

Industry Applications

RC hydraulic cylinders find applications in several sectors, highlighting their versatility. In the construction industry, they are used in excavators, loaders, and other heavy machinery, where their compact design allows for operation in confined spaces. In agriculture, these cylinders enable precision in equipment like planters and harvesters, improving yield and efficiency. Furthermore, in manufacturing, RC hydraulic cylinders play a crucial role in automated systems and assembly lines, enhancing throughput and reducing labor costs.

Quality Assurance and Standards

Quality assurance is another vital aspect of RC hydraulic cylinder manufacturing. Manufacturers adhere to stringent quality control measures and industry standards to ensure that their products are durable and reliable. Certifications from recognized organizations can provide customers with confidence in the products they purchase. High-quality hydraulic cylinders minimize the risk of failures, thereby reducing maintenance costs and enhancing safety in industrial operations.

Conclusion

In conclusion, RC hydraulic cylinder manufacturers are pivotal in shaping the future of various industries by providing innovative and customized solutions. Their commitment to quality, technological advancements, and customer satisfaction plays a crucial role in enhancing the efficiency and reliability of hydraulic systems. As industries continue to evolve and demand more from their machinery, the role of these manufacturers will become increasingly important, driving progress and innovation across the sector. The collaboration between manufacturers and end-users ultimately leads to enhanced productivity and cost-effectiveness, paving the way for a more efficient industrial landscape.

-

Fork Lift Power Units - Hebei Shenghan | Efficiency, Reliability

NewsJul.13,2025

-

1.5-Ton Turbocharged Cylinder-Hebei Shenghan|Hydraulic Solution,Energy Efficiency

NewsJul.13,2025

-

Auto Hoist Power Units-Hebei Shenghan|Efficiency&Industrial Lifting

NewsJul.13,2025

-

Double Acting Power Units-Hebei Shenghan|Hydraulic Solutions,Industrial Efficiency

NewsJul.13,2025

-

1.5 Ton Lifting Cylinder 70/82-40-290-535 - High-Performance Hydraulic Solution | Hebei Shenghan

NewsJul.13,2025

-

Fork Lift Power Units - Hebei Shenghan | Efficiency&Reliability

NewsJul.13,2025